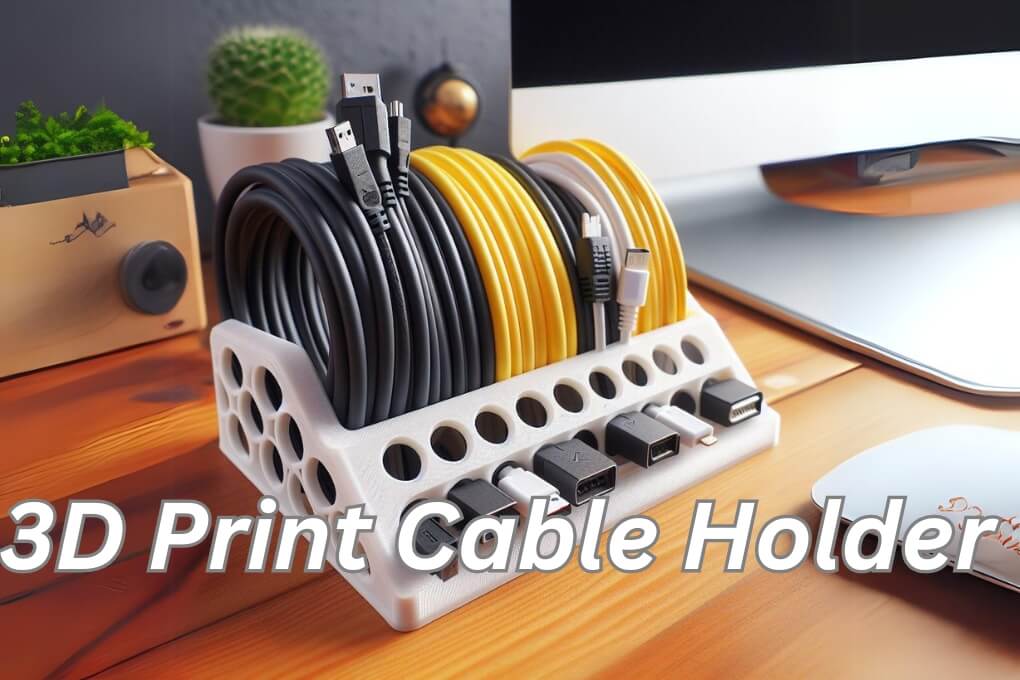

A 3D print cable holder is a useful accessory that helps keep cables organized and prevents them from tangling or getting damaged.

The convenience of modern technology often comes with a downside – a tangled mess of cables. Whether it’s charging cables, USB cords, or headphone wires, they always seem to end up in a jumbled mess. But fear not, there is a solution: a 3D print cable holder. This handy accessory can be customized to fit your specific needs and helps keep your cables organized, preventing them from tangling or getting damaged. In this article, we will explore the benefits of using a 3D print cable holder and how it can make your life easier.

I. Benefits of Using a 3D Printed Cable Holder

When it comes to organizing cables, a 3D printed cable holder can be a game-changer. Whether you’re dealing with a tangle of wires behind your desk or trying to keep your charging cables neatly organized, a cable holder can make a world of difference.

Here are some of the benefits of using a 3D printed cable holder:

1. Cable Management

One of the main advantages of using a 3D printed cable holder is improved cable management. With a cable holder, you can keep your cables neatly organized and prevent them from getting tangled or damaged. This not only makes your workspace look tidier, but it also makes it easier to find and access the cables you need.

2. Customization

Another great benefit of 3D printed cable holders is the ability to customize them to fit your specific needs. With traditional cable holders, you’re often limited to standard sizes and designs. However, with 3D printing, you can create a cable holder that perfectly fits your cables and matches your personal style.

3. Cost-Effective

3D printing technology has made significant advancements in recent years, making it more accessible and cost-effective than ever before. Instead of purchasing expensive cable holders, you can simply download a 3D model and print it yourself. This not only saves you money but also allows you to create multiple cable holders for different areas of your home or office.

4. Eco-Friendly

Using 3D printed cable holders is also an eco-friendly choice. By printing your own cable holders, you reduce the need for mass-produced plastic products that often end up in landfills. Additionally, you can use recycled or biodegradable materials for your 3D prints, further reducing your environmental impact.

5. Versatility

Lastly, 3D printed cable holders offer versatility in terms of design and functionality. Whether you need a simple clip to hold a single cable or a complex organizer to manage multiple cables, 3D printing allows you to create a wide range of cable holder designs. You can also experiment with different materials and colors to match your aesthetic preferences.

Overall, using a 3D printed cable holder provides numerous benefits, including improved cable management, customization options, cost-effectiveness, eco-friendliness, and versatility. With the right design and materials, you can create cable holders that perfectly suit your needs and enhance your workspace.

II. How to Design a 3D Printed Cable Holder

Designing a 3D printed cable holder is a straightforward process that requires a basic understanding of 3D modeling software.

Follow these steps to create your own custom cable holder:

- Identify your cable needs: Before starting the design process, determine the number and types of cables you need to organize. This will help you determine the size and shape of your cable holder.

- Select a 3D modeling software: There are various 3D modeling software options available, both free and paid. Choose one that suits your skill level and preferences. Some popular choices include Autodesk Fusion 360, Tinkercad, and SketchUp.

- Create a new project: Open your chosen 3D modeling software and create a new project. Set the dimensions of your project based on the size of the cable holder you want to design.

- Sketch the basic shape: Use the drawing tools in the software to sketch the basic shape of your cable holder. Consider factors such as the number of cable slots, the overall size, and any additional features you want to include, such as hooks or clips.

- Add cable slots: Once you have the basic shape, add slots or grooves where the cables will fit. Ensure that the slots are wide enough to accommodate the cables without being too loose.

- Refine the design: Take the time to refine your design, making adjustments as necessary. Consider factors such as aesthetics, functionality, and ease of printing.

- Export the design: Once you are satisfied with your design, export it as a suitable file format for 3D printing, such as STL or OBJ.

- Prepare for printing: Import the exported design file into your chosen 3D printing software. Adjust the settings as needed, such as infill density and layer height, to ensure a successful print.

- Print the cable holder: Send the design file to your 3D printer and start the printing process. Monitor the print to ensure it is progressing smoothly and make any necessary adjustments.

- Post-processing: Once the print is complete, remove any support structures and clean up the cable holder if needed. You can also sand or paint the holder to achieve the desired finish.

By following these steps, you can easily design and 3D print a custom cable holder that meets your specific needs. Remember to experiment and iterate on your designs to achieve the best results.

III. Materials and Tools Needed for 3D Printing a Cable Holder

In order to successfully 3D print a cable holder, you will need the following materials and tools:

Materials:

- 3D Printer Filament: Choose a filament that is suitable for your 3D printer and the specific requirements of your cable holder design. Common filament options include PLA, ABS, and PETG.

- Adhesive: Depending on the material of your filament, you may need adhesive to ensure that the different parts of your cable holder stay securely attached.

Tools:

- 3D Printer: You will need access to a 3D printer in order to bring your cable holder design to life. Make sure your printer is properly calibrated and in good working condition.

- Computer and 3D Modeling Software: You will need a computer with 3D modeling software installed to create or modify your cable holder design. Popular options include Autodesk Fusion 360, Tinkercad, and SketchUp.

- Calipers or Measuring Tools: Accurate measurements are crucial when designing a cable holder that fits your specific cables. Use calipers or other measuring tools to ensure precise dimensions.

- Utility Knife or Sandpaper: After printing, you may need to remove any support structures or smooth out rough edges on your cable holder. A utility knife or sandpaper can be useful for this.

By having these materials and tools ready, you will be well-prepared to successfully 3D print a cable holder that meets your needs and keeps your cables organized.

IV. Tips for Successfully Printing a 3D Cable Holder

When it comes to 3D printing a cable holder, there are a few important tips to keep in mind to ensure a successful print.

Follow these guidelines to achieve the best results:

- Choose the right filament: Select a filament that is suitable for cable management, such as PLA or ABS. These materials are durable and can withstand the weight and stress of holding cables in place.

- Optimize your design: Before printing, make sure your cable holder design is optimized for 3D printing. This includes ensuring proper wall thickness, adding support structures if necessary, and checking for any potential issues that could affect the print quality.

- Use a heated bed: If your 3D printer has a heated bed, it is recommended to use it when printing a cable holder. This helps to prevent warping and ensures better adhesion of the printed object to the build plate.

- Adjust the print settings: Fine-tune your print settings to achieve the desired level of detail and strength for your cable holder. This includes adjusting the layer height, print speed, and infill density.

- Consider adding additional supports: Depending on the complexity of your cable holder design, you may need to add support structures to prevent sagging or collapsing during the printing process. These supports can be easily removed after printing.

- Monitor the printing process: Keep an eye on the 3D printer while it is printing the cable holder. This allows you to quickly address any issues that may arise, such as filament jams or adhesion problems.

- Post-process if necessary: Once the cable holder is printed, you may need to do some post-processing to remove any rough edges or imperfections. Sanding or filing can help achieve a smoother finish.

By following these tips, you can ensure a successful 3D print of a cable holder that meets your needs and keeps your cables organized and tangle-free.

FAQ – 3D Print Cable Holder

What is a 3D print cable holder?

A 3D print cable holder is a small device that is designed to hold and organize cables, preventing them from tangling or becoming messy. It is created using 3D printing technology, allowing for customization and unique designs.

How does a 3D print cable holder work?

A 3D print cable holder typically consists of a base and multiple slots or clips where cables can be inserted. The cables are securely held in place, preventing them from moving around or tangling. This helps to keep your workspace neat and organized.

Can I customize the design of a 3D print cable holder?

Yes, one of the advantages of 3D printing is the ability to customize designs. You can modify the size, shape, and even add your own personal touches to the cable holder. There are various 3D modeling software available that can help you create your own unique design.

What materials are used for 3D print cable holders?

3D print cable holders can be made from a variety of materials, including PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), or PETG (polyethylene terephthalate glycol-modified). These materials are commonly used in 3D printing and offer durability and strength.

Are 3D print cable holders easy to install?

Yes, most 3D print cable holders are designed to be easily installed. They often have adhesive backing or mounting holes that allow you to attach them to your desk, wall, or any other surface. Some cable holders may require screws or other fasteners for a more secure installation.

Can a 3D print cable holder hold different types of cables?

Yes, 3D print cable holders are versatile and can hold various types of cables, including USB cables, HDMI cables, power cords, and more. The slots or clips on the cable holder are usually designed to accommodate different cable thicknesses.

Are 3D print cable holders suitable for both home and office use?

Absolutely! 3D print cable holders are perfect for both home and office environments. Whether you want to organize your computer cables at your desk or manage the cords behind your entertainment system, a cable holder can help keep everything tidy and easily accessible.

Can I purchase pre-designed 3D print cable holders?

Yes, there are many pre-designed 3D print cable holders available for purchase. You can find a wide range of designs on various online platforms that offer 3D printed products. Alternatively, you can also download free or paid designs from websites specializing in 3D printable files.

How do I clean a 3D print cable holder?

Most 3D print cable holders can be easily cleaned using a damp cloth or sponge. If the holder is made from a plastic material, you can also wash it with mild soap and water. Avoid using harsh chemicals or abrasive materials that may damage the surface of the cable holder.

Can I use a 3D print cable holder for outdoor applications?

While some 3D print cable holders may be suitable for outdoor use, it is important to consider the material used and its resistance to weather conditions. PLA, for example, may not withstand extreme heat or prolonged exposure to sunlight. It is recommended to choose a material specifically designed for outdoor applications if needed.

Conclusion On 3D Print Cable Holder

In conclusion, a 3D printed cable holder is a practical and efficient solution for organizing and managing cables. With its customizable design and easy-to-use functionality, it offers a seamless cable management experience. By utilizing 3D printing technology, you can create a cable holder that perfectly fits your needs and eliminates clutter. So, why wait? Start 3D printing your own cable holder today and enjoy a clutter-free workspace!