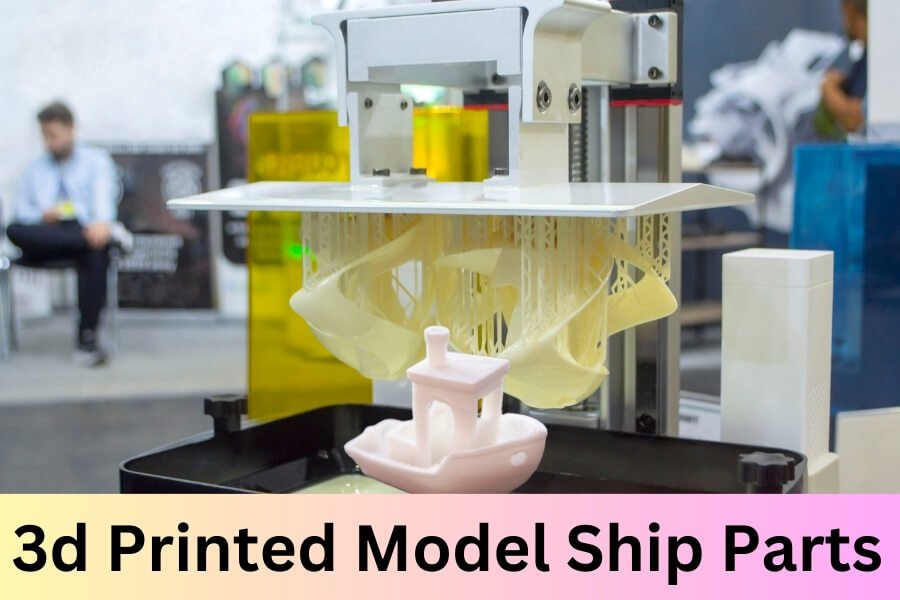

3D printed model ship parts offer high precision and customization for hobbyists and professionals. With advanced technology, these parts can be replicated with intricate details and accurate measurements, making them ideal for model shipbuilding enthusiasts.

Model shipbuilding is a popular hobby for many people who enjoy recreating historical vessels or creating unique designs.

3D printed model ship parts provide a level of precision and customization that traditional manufacturing methods cannot match.

With the ability to replicate intricate details and achieve accurate measurements, these parts offer an unparalleled level of intricacy and authenticity for model ships.

From small components to large structural elements, 3D printing allows enthusiasts to bring their visions to life with meticulous accuracy and exceptional quality.

Whether it’s for personal enjoyment or professional purposes, the availability of 3D printed model ship parts has enhanced the world of model shipbuilding.

The Advantages Of 3d Printed Model Ship Parts

1. Precision And Accuracy

3D printing technology offers unparalleled precision and accuracy in creating model ship parts.

With the ability to produce intricate details and fine features, 3D printed parts ensure that every component fits perfectly, enhancing the overall quality and realism of the model.

The precision of 3D printing also allows for the creation of complex geometries and intricate designs that are challenging to achieve through traditional manufacturing methods.

2. Customization Options

One of the significant advantages of 3D printed model ship parts is the extensive customization options they provide.

From adjusting the size and shape of components to incorporating personalized details, 3D printing empowers modelers to create unique and bespoke pieces for their ship models.

This level of customization allows enthusiasts to bring their creative visions to life and tailor their models to specific historical references or personal preferences.

3d Printing Technology In Model Shipbuilding

The integration of 3D printing technology in model shipbuilding has revolutionized the traditional manufacturing process.

With the advent of advanced 3D printing techniques, creating intricate ship parts has become more efficient and precise than ever before.

Model ship enthusiasts and professionals now have the capability to produce highly detailed and customized components with ease, adding a new dimension of accuracy to their projects.

The potential benefits of additive manufacturing in model shipbuilding are vast.

Additive manufacturing allows for the creation of complex geometries and intricate details that are challenging or even impossible to achieve using conventional manufacturing methods.

Furthermore, it enables the rapid prototyping of designs, reducing the time and cost associated with traditional manufacturing processes.

Additionally, 3D printing technology empowers shipbuilders to experiment with innovative designs and materials, leading to a new level of creativity and flexibility in their craft.

Choosing The Right 3d Printing Materials

When it comes to creating the perfect model ship, choosing the right 3D printing materials is crucial.

The right materials will not only ensure the durability and finish of your model ship but also determine the overall quality and aesthetics of the final product.

In this guide, we’ll explore the key considerations for ship models, focusing on durability and finish, to help you make an informed decision for your 3D printed model ship parts.

1. Considerations For Ship Models

- Scale and Detail: Consider the scale and level of detail required for your model ship. Different materials offer varying levels of precision and can accommodate different scales.

- Strength and Flexibility: Evaluate the strength and flexibility needed for specific components of the model. Some parts may require more durability, especially if they are subject to manipulation or external forces.

- Compatibility: Ensure that the chosen material is compatible with the 3D printing technology you plan to use. Different 3D printers may have specific requirements for materials.

2. Durability And Finish

When it comes to 3D printed model ship parts, durability and finish are paramount. The material you choose should be able to withstand handling and potential environmental factors, while also delivering a high-quality surface finish.

Here are a few key factors to consider:

- Material Strength: Look for materials with high tensile strength and impact resistance to ensure the longevity of your model ship parts.

- Surface Finish: Consider the level of detail and smoothness required for the surface finish. Some materials may require minimal post-processing for a polished appearance.

- Environmental Factors: Assess the exposure of the model ship to elements such as moisture, heat, or UV light, and select a material that can withstand these conditions.

Designing 3d Model Ship Parts

When it comes to designing 3D model ship parts, precision and attention to detail are essential.

Whether you are a hobbyist or a professional model shipbuilder, the ability to craft intricate and accurate components can greatly enhance the overall look and quality of your model ship.

In this blog post, we will explore the process of designing 3D model ship parts, including the software utilized, customization techniques, and the benefits of leveraging 3D printing technology for this purpose.

1. Cad Software For Model Shipbuilding

When it comes to designing 3D model ship parts, utilizing advanced Computer-Aided Design (CAD) software is crucial.

CAD software enables model shipbuilders to create highly detailed and precise digital models of ship components.

Popular CAD software such as Autodesk Fusion 360, SolidWorks, or Rhino 3D offer robust tools for designing intricate ship parts with utmost accuracy.

These software applications provide features such as parametric modeling, assembly design, and simulation capabilities, empowering model shipbuilders to bring their designs to life with exceptional precision and efficiency.

2. Customization Techniques

Customization is a key aspect of designing 3D model ship parts. With the use of CAD software, model shipbuilders can tailor each component to meet specific project requirements.

This includes adjusting dimensions, adding intricate details such as engravings or embellishments, and fine-tuning the overall aesthetics of the ship parts.

Leveraging customization techniques allows for a high degree of personalization, enabling model shipbuilders to create unique and bespoke components that align perfectly with their vision.

Finishing And Detailing 3d Printed Ship Components

The process of completing 3D printed model ship parts involves finishing and detailing to enhance the overall realism and re-create an authentic replica.

This stage is crucial for achieving a high-quality result, and it offers the opportunity to add intricate details and achieve stunning visual effects.

1. Painting And Weathering Techniques

When it comes to painting 3D printed ship components, utilizing the right techniques can truly bring the model to life.

Consider using fine brushes and high-quality acrylic or enamel paints to achieve a smooth and realistic finish.

Weathering techniques, such as dry brushing and washes, can add depth and character to the ship parts, creating the appearance of age and wear.

2. Enhancing Realism With Fine Details

Adding fine details to 3D printed ship components can significantly enhance the overall realism of the model.

Small accessories, such as ropes, pulleys, and railings, can be crafted using fine filaments or additional 3D printing processes.

These intricate details not only visually enrich the model but also provide a tactile experience, making the finished model more engaging.

Quality Control And Testing

Quality control and testing are crucial aspects of ensuring the reliability and accuracy of 3D printed model ship parts.

With the intricate details and precision required for these parts, thorough inspection processes are essential to deliver high-quality components.

1. Ensuring Fit And Functionality

Ensuring the fit and functionality of 3D printed model ship parts is a critical step in the quality control process.

Each component must be meticulously measured and tested to ensure precise dimensions and compatibility with other parts.

This involves rigorous testing procedures to validate the functional integrity of the parts, guaranteeing that they meet the required specifications.

2. Surface Finish Inspections

The surface finish of 3D printed model ship parts plays a significant role in their aesthetic appeal and structural integrity.

Surface finish inspections involve detailed examinations to assess the smoothness, texture, and overall quality of the printed parts.

Any imperfections are identified and addressed to maintain the superior finish required for these components.

The Future Of 3d Printed Ship Model Parts

1. Emerging Technologies And Innovations

3D printing technology has revolutionized the ship model parts industry. With the advancement of 3D printing technologies, the future holds immense potential for creating highly detailed and accurate ship model parts.

Innovations such as multi-material 3D printing and faster printing speeds are reshaping the way modelers create intricate and customized ship parts.

The ability to replicate complex designs with precision is transforming the landscape of ship model making.

2. Impact On Traditional Model Making Industry

The emergence of 3D printed ship model parts has significantly impacted the traditional model making industry.

Traditional techniques have been complemented, if not replaced, by this disruptive technology. Modelers are now able to produce parts that were once labor-intensive and time-consuming with unprecedented speed and accuracy.

The accessibility of 3D printing has opened up new possibilities for creating detailed and intricate ship model parts, disrupting the traditional methods of production and introducing a new era of creativity and precision.

Frequently Asked Questions For 3d Printed Model Ship Parts

What Are The Benefits Of 3d Printed Model Ship Parts?

3D printed model ship parts offer high precision, customization, and cost-effectiveness for hobbyists and collectors.

How Durable Are 3d Printed Model Ship Parts?

With the right materials, 3D printed ship parts are durable and strong enough for display and handling.

Can 3d Printed Model Ship Parts Be Customized?

Yes, 3D printing allows for unique customization of ship parts according to individual preferences and specifications.

What Materials Are Used For 3d Printed Model Ship Parts?

Various materials like PLA, ABS, and resin are commonly used, each having specific strengths for different purposes.

Are 3d Printed Model Ship Parts Accurate To The Original Design?

Yes, 3D printing technology ensures high precision, enabling accurate replication of intricate ship designs.

How Can I Paint 3d Printed Model Ship Parts?

3D printed ship parts can be painted using acrylic paints, allowing for detailed and realistic coloring.

Are 3d Printed Model Ship Parts Suitable For Different Scales?

Whether it’s a large replica or a miniature model, 3D printing can cater to various scales of ship parts.

Can 3d Printed Model Ship Parts Be Used For Functional Models?

Some 3D printed ship parts are functional and can be incorporated into the working mechanisms of model ships.

What Level Of Detail Is Achievable With 3d Printed Ship Parts?

High-detail 3D printing can capture intricate features, adding realism and authenticity to model ship parts.

How Does 3d Printing Contribute To The Model Shipbuilding Hobby?

3D printing revolutionizes model shipbuilding by offering accessibility, creativity, and innovative possibilities for enthusiasts.

Conclusion on 3d Printed Model Ship Parts

3D printed model ship parts offer a unique and customizable approach to ship model building.

The ease of replication and intricate details provided by 3D printing technology have revolutionized the hobby and industry.

Embracing this innovation allows for greater creativity and precision, enhancing the overall experience for enthusiasts and professionals alike.