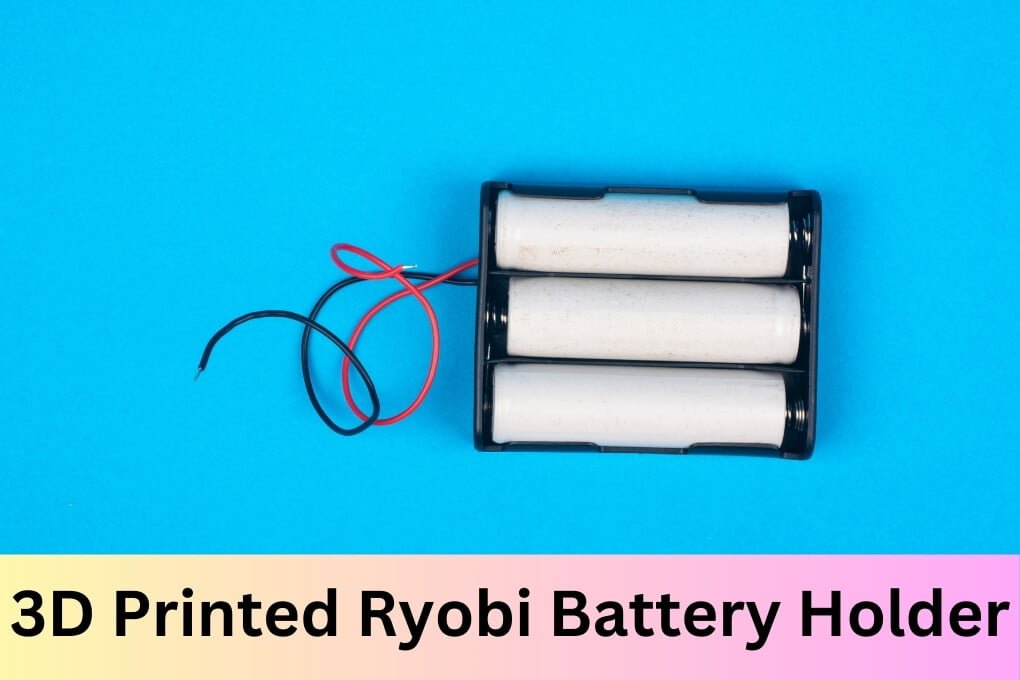

Yes, it is possible to 3D print a Ryobi battery holder.

If you are looking for a convenient and customized solution to store and organize your Ryobi batteries, 3D printing can provide a practical option. By designing and printing a battery holder specifically tailored to fit Ryobi batteries, you can ensure a snug fit and easy access to your power source.

With the versatility of 3D printing technology, you can create a battery holder that meets your specific needs and preferences.

I. Benefits of 3D Printing for Ryobi Battery Holders

When it comes to Ryobi battery holders, 3D printing offers a multitude of benefits. As an avid user of Ryobi power tools, I have discovered the advantages of creating custom battery holders using this innovative technology.

Here are some key benefits:

1. Customization

With 3D printing, I have the freedom to design and create battery holders that perfectly fit my specific needs. Whether I want a compact holder for easy portability or a larger one for holding multiple batteries, I can easily customize the design to suit my requirements. This level of customization ensures a snug fit, preventing any unnecessary movement or damage to the batteries.

2. Cost Savings

By utilizing 3D printing, I have been able to save a significant amount of money on Ryobi battery holders. Instead of purchasing pre-made holders from the market, which can be expensive, I can simply design and print my own at a fraction of the cost. This cost-effective solution allows me to allocate my budget towards other essential tools or accessories.

3. Quick Prototyping

One of the greatest advantages of 3D printing is the ability to rapidly prototype designs. When I have an idea for a new battery holder design, I can quickly create a 3D model and print it within a matter of hours. This allows me to test and iterate on different designs until I find the perfect solution. The speed of prototyping offered by 3D printing saves me valuable time and resources.

4. Enhanced Durability

Traditional battery holders can sometimes be prone to wear and tear, especially with regular use. However, 3D printed battery holders can be made with durable materials such as ABS or PETG, which offer excellent strength and impact resistance. This ensures that the battery holder can withstand the rigors of everyday use and provide long-lasting functionality.

5. Eco-Friendly Solution

By utilizing 3D printing to create my Ryobi battery holders, I am actively contributing to a more sustainable future. Instead of relying on mass-produced plastic holders that may end up in landfills, I can create my own holders using recyclable materials. This eco-friendly approach aligns with my values of reducing waste and minimizing my environmental footprint.

II. How to Design a 3D Printed Ryobi Battery Holder

Designing a 3D printed Ryobi battery holder is a great way to customize and optimize your power tool experience. With 3D printing technology, you have the freedom to create a battery holder that perfectly fits your needs.

Here are the steps to design a 3D printed Ryobi battery holder:

1. Measure the Dimensions

The first step is to measure the dimensions of your Ryobi battery. This includes the length, width, and height of the battery, as well as the location and size of the battery terminals. These measurements will be crucial in creating a snug and secure fit for your battery holder.

2. Choose a CAD Software

Next, you’ll need to choose a computer-aided design (CAD) software to create your battery holder design. There are many options available, ranging from beginner-friendly software to more advanced options. Some popular CAD software include AutoCAD, SolidWorks, and Fusion 360. Choose a software that you feel comfortable with and that suits your design needs.

3. Create the Design

Once you have chosen a CAD software, you can start creating your battery holder design. Begin by creating a base that matches the dimensions of your Ryobi battery. Then, design the slots or compartments to hold the battery securely in place. Consider adding additional features such as clips or latches to ensure a tight fit.

4. Test and Refine

After creating your initial design, it’s important to test it before 3D printing. Use your CAD software to simulate the fit of the battery in the holder and make any necessary adjustments. This step will help you identify and fix any potential issues before moving forward.

5. Export the Design

Once you are satisfied with your battery holder design, you can export it as a file format that is compatible with 3D printing. The most common file formats for 3D printing are STL (Standard Tessellation Language) and OBJ (Object File Format). Make sure to check the requirements of your 3D printer to ensure compatibility.

6. Prepare for 3D Printing

Before sending your design to the 3D printer, you’ll need to prepare the file. This involves slicing the design into layers using slicing software. Slicing software such as Cura or Simplify3D will generate the instructions for your 3D printer to create each layer of your battery holder.

7. Print the Battery Holder

Now it’s time to 3D print your battery holder! Make sure your 3D printer is properly calibrated and loaded with the appropriate filament material. Follow the instructions provided by your 3D printer manufacturer to ensure a successful print. Depending on the size and complexity of your design, the printing process may take several hours.

8. Post-Processing

Once the 3D printing is complete, remove the battery holder from the print bed. Carefully clean and remove any support structures if necessary. Sand down any rough edges or imperfections to achieve a smooth finish. Your battery holder is now ready to be used!

Designing a 3D printed Ryobi battery holder allows you to create a customized and functional accessory for your power tools. By following these steps and utilizing the power of 3D printing technology, you can optimize your battery storage and enhance your overall tool experience.

III. Materials and Tools Required for 3D Printing a Ryobi Battery Holder

When it comes to 3D printing a Ryobi battery holder, it is important to have the right materials and tools at your disposal.

Here is a list of what you will need:

1 .Materials:

- PLA filament: PLA (polylactic acid) is a commonly used filament for 3D printing. It is durable and easy to work with, making it ideal for creating functional battery holders.

- Adhesive: Depending on the design of your battery holder, you may need adhesive to secure the different parts together. Make sure to choose an adhesive that is compatible with PLA.

2. Tools:

- 3D printer: Of course, you will need a 3D printer to bring your design to life. Make sure your printer is in good working condition and properly calibrated.

- Computer: You will need a computer to design your battery holder using CAD (Computer-Aided Design) software. There are many free and paid options available, so choose one that suits your needs.

- Calipers: Calipers are essential for accurately measuring the dimensions of your Ryobi batteries. This will ensure a snug fit and prevent any potential issues.

- Spatula or scraper: A spatula or scraper is useful for removing the printed battery holder from the printer’s build plate without damaging it.

- Sandpaper: Depending on the quality of your 3D print, you may need to smooth out any rough edges or imperfections with sandpaper.

3. Table:

| Materials | Tools |

|---|---|

| PLA filament | 3D printer |

| Adhesive | Computer |

| Calipers | |

| Spatula or scraper | |

| Sandpaper |

Having the right materials and tools is crucial for a successful 3D printing project. Make sure to gather everything you need before getting started, and always prioritize safety when working with 3D printers and related tools.

IV. Tips and Tricks for 3D Printing a Functional Ryobi Battery Holder

When it comes to 3D printing a Ryobi battery holder, there are a few tips and tricks that can help ensure a successful and functional print.

Here are some key things to keep in mind:

1. Design Considerations

Before you start printing, it’s important to carefully consider the design of your battery holder. Make sure to take accurate measurements of the battery and consider any additional features or supports that may be necessary for a secure fit. A well-designed battery holder will ensure that the battery remains firmly in place during use.

2. Print Orientation

The orientation in which you print your battery holder can have a significant impact on the overall strength and durability of the print. Experiment with different orientations to find the one that provides the best balance between strength and print quality. Consider using support structures if needed to prevent any sagging or warping during the printing process.

3. Layer Height and Infill

The layer height and infill density are important settings to consider when printing a battery holder. A lower layer height will result in a smoother and more detailed print, while a higher infill density will provide added strength and stability. Finding the right balance between these settings is crucial for a functional battery holder.

4. Material Selection

Choosing the right material for your battery holder is essential for its functionality. PLA (Polylactic Acid) is a commonly used material for 3D printing due to its ease of use and wide availability. However, if you require a battery holder with higher heat resistance or durability, consider using ABS (Acrylonitrile Butadiene Styrene) or PETG (Polyethylene Terephthalate Glycol).

5. Post-Processing and Finishing

Once your battery holder is printed, it’s important to properly finish and post-process the print to ensure a smooth and functional result. This may include removing any support structures, sanding or filing any rough edges, and ensuring a proper fit for the battery. Taking the time to properly finish your print will greatly enhance its overall quality and functionality.

6. Test and Iterate

After printing your battery holder, it’s important to test it with the actual battery to ensure a proper fit and functionality. If any adjustments or modifications are needed, don’t be afraid to iterate and reprint the design until you achieve the desired result. Testing and iterating will help you fine-tune your design and create a functional battery holder.

7. Safety Precautions

When 3D printing, it’s important to follow proper safety precautions. Ensure that your printer is in a well-ventilated area and that you are using the appropriate safety equipment, such as gloves and goggles. Additionally, always monitor your printer during the printing process to prevent any potential hazards or accidents.

8. Learn from Others

Don’t be afraid to seek inspiration and learn from others who have successfully 3D printed battery holders. Join online communities or forums dedicated to 3D printing to gain valuable insights and tips from experienced makers. Learning from others can help you avoid common pitfalls and achieve better results with your own prints.

9. Have Patience and Persistence

3D printing can sometimes be a trial-and-error process, so it’s important to have patience and persistence. Don’t get discouraged if your first print doesn’t turn out as expected – learn from the experience and make the necessary adjustments for your next attempt. With practice and perseverance, you’ll be able to 3D print a functional Ryobi battery holder.

10. Enjoy the Process

Lastly, remember to enjoy the process of 3D printing. It’s a creative and rewarding hobby that allows you to bring your ideas to life. Embrace the challenges and successes along the way, and have fun experimenting with different designs and materials to create the perfect Ryobi battery holder.

Frequently Asked Questions For 3D Printed Ryobi Battery Holder

What is a 3D printed Ryobi battery holder?

A 3D printed Ryobi battery holder is a custom-designed accessory that can securely hold Ryobi batteries in place. It is created using a 3D printer, which allows for precise and tailored dimensions.

Why should I use a 3D printed battery holder instead of the original one?

A 3D printed battery holder offers several advantages over the original one. It can be customized to fit specific needs, provides better durability, and allows for easier access to the batteries.

Can I use a 3D printed battery holder with any Ryobi battery?

Yes, a 3D printed battery holder can be designed to fit any Ryobi battery model. The dimensions and specifications can be adjusted accordingly to ensure a perfect fit.

How do I obtain a 3D printed battery holder?

You can obtain a 3D printed battery holder by either designing and printing it yourself if you have access to a 3D printer or by purchasing one from online marketplaces or local 3D printing services.

Is it difficult to install a 3D printed battery holder?

No, installing a 3D printed battery holder is a simple process. It usually involves removing the original battery holder and replacing it with the 3D printed one, ensuring a secure fit.

Can I modify the design of a 3D printed battery holder?

Yes, one of the advantages of 3D printed battery holders is their customizability. You can modify the design to suit your preferences, such as adding additional features or adjusting the size.

Are 3D printed battery holders safe to use?

When designed and printed correctly, 3D printed battery holders are safe to use. It is important to ensure the holder provides a secure fit and does not interfere with the battery’s electrical contacts.

Can I share 3D printed battery holder designs with others?

Yes, you can share 3D printed battery holder designs with others. Many online communities and platforms encourage the sharing of 3D printable designs to foster collaboration and innovation.

How long does it take to 3D print a battery holder?

The printing time for a 3D printed battery holder can vary depending on the size and complexity of the design. It can range from a few hours to several hours, or even overnight for larger designs.

Can I sell 3D printed battery holders?

Yes, you can sell 3D printed battery holders as long as you have the rights to the design or if it is an original creation. It is essential to comply with any copyright or licensing restrictions when selling 3D printed products.

Conclusion on 3D Printed Ryobi Battery Holder

With the convenience and versatility of 3D printing technology, creating a custom Ryobi battery holder has never been easier. By utilizing a 3D printer, you can design and print a battery holder that perfectly fits your Ryobi batteries, ensuring a secure and organized storage solution.

Embrace the power of 3D printing and take control of your battery organization with a personalized Ryobi battery holder.