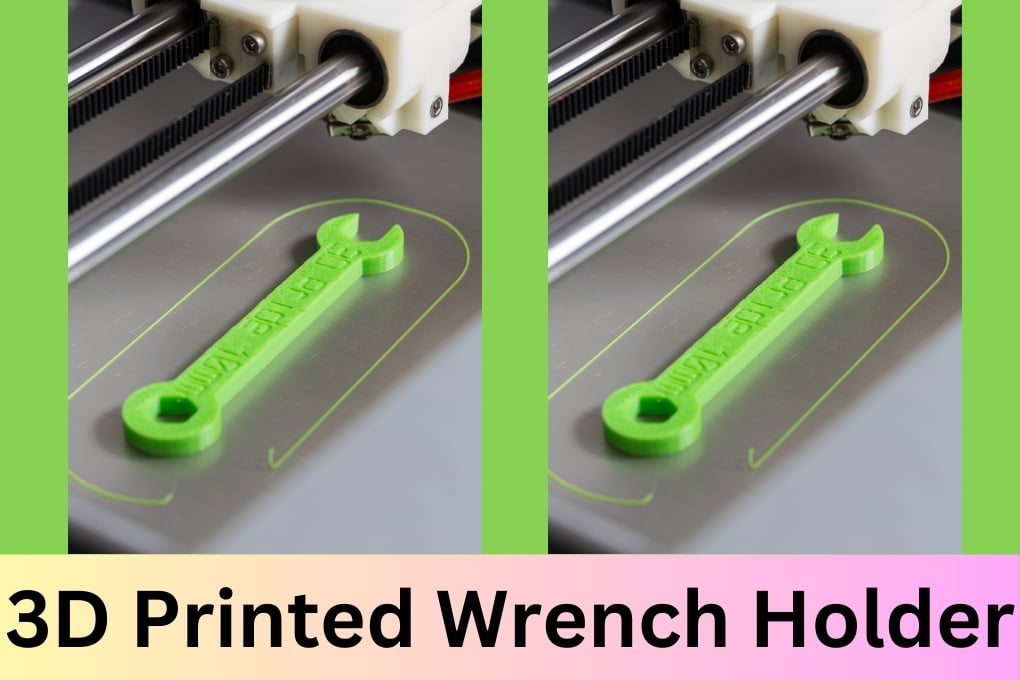

Yes, a 3D printed wrench holder is a practical and customizable solution for organizing and storing your wrenches.

If you’re tired of misplacing your wrenches or struggling to find the right one when you need it, a 3D printed wrench holder can be the perfect solution.

With its customizable design, you can create a holder that perfectly fits your wrenches, keeping them organized and easily accessible. Whether you’re a DIY enthusiast or a professional mechanic, a 3D printed wrench holder can help streamline your work and save you time.

I. Benefits of a 3D Printed Wrench Holder

When it comes to organizing tools, a 3D printed wrench holder can be a game-changer. Not only does it provide a convenient way to store and access your wrenches, but it also offers several other benefits.

Here are some of the advantages of using a 3D printed wrench holder:

1. Improved Organization

One of the main benefits of a 3D printed wrench holder is that it helps you keep your wrenches organized. With designated slots for each wrench, you no longer have to waste time searching for the right tool. This not only saves you time but also reduces frustration during your projects.

2. Space Saving

Another advantage of a 3D printed wrench holder is that it helps you save space in your toolbox or workshop. By neatly arranging your wrenches in a compact holder, you can free up valuable space for other tools or equipment. This is especially beneficial for those with limited storage space.

3. Easy Accessibility

With a 3D printed wrench holder, your wrenches are easily accessible whenever you need them. You can quickly identify the wrench you need and grab it without having to sift through a jumbled mess of tools. This not only increases efficiency but also reduces the risk of accidents or injuries.

4. Protection and Durability

A 3D printed wrench holder provides a protective and durable storage solution for your wrenches. The holder prevents the tools from banging into each other, which can lead to damage or wear over time. Additionally, the 3D printed material used for the holder is often sturdy and long-lasting, ensuring that your wrenches are well-protected for years to come.

5. Customizability

One of the greatest advantages of 3D printing is the ability to customize designs. With a 3D printed wrench holder, you can tailor the design to fit your specific needs. Whether you have a unique set of wrenches or prefer a certain arrangement, you can create a personalized holder that perfectly suits your requirements.

Overall, a 3D printed wrench holder offers numerous benefits, including improved organization, space-saving, easy accessibility, protection, durability, and customizability. By investing in a 3D printed wrench holder, you can enhance your tool storage system and make your projects more efficient and enjoyable.

II. How to Design a 3D Printed Wrench Holder

Designing a 3D printed wrench holder is a relatively simple process that requires some basic knowledge of 3D modeling software.

Follow these steps to create your own customized wrench holder:

- Measure your wrenches: Start by measuring the dimensions of your wrenches, including the length, width, and height. This will help you determine the appropriate size for your wrench holder.

- Choose a 3D modeling software: There are several 3D modeling software options available, both free and paid. Choose one that you are comfortable with and that suits your needs.

- Create a new project: Open the 3D modeling software and create a new project. Set the dimensions of the project based on the measurements of your wrenches.

- Design the wrench holder: Use the tools and features of the 3D modeling software to design the wrench holder. Start by creating a base that will hold the wrenches securely. Then, add individual slots or compartments for each wrench.

- Consider additional features: Depending on your preferences, you can add additional features to your wrench holder, such as a handle for easy transportation or a wall-mounting option.

- Check for compatibility: Before finalizing your design, make sure that it is compatible with your 3D printer. Check the specifications of your printer and adjust your design accordingly.

- Export the design: Once you are satisfied with your design, export it as a 3D printable file format, such as STL or OBJ.

By following these steps, you can design a customized wrench holder that perfectly fits your wrenches and meets your specific needs. The flexibility of 3D printing allows you to create a unique and personalized tool organizer that can help improve efficiency and organization in your workspace.

III. Materials and Tools Required for 3D Printing a Wrench Holder

When it comes to 3D printing a wrench holder, there are a few materials and tools that you will need to have on hand.

These include:

1. Materials:

- 3D printer filament: Choose a filament material that suits your needs, such as PLA or ABS.

- Wrench holder design file: Download or create a 3D model file of the wrench holder you want to print.

2. Tools:

- 3D printer: You will need access to a 3D printer to bring your design to life.

- Slicer software: Use a slicer program to prepare your design file for printing, adjusting settings such as layer height and print speed.

- Computer: A computer is necessary for designing the wrench holder, preparing the file for printing, and sending it to the 3D printer.

- Calipers: Calipers are useful for measuring the dimensions of your wrenches to ensure a proper fit in the holder.

- Sanding tools: Depending on the quality of your 3D print, you may need sandpaper or a file to smooth out any rough edges.

Having the right materials and tools is crucial for a successful 3D print of a wrench holder. Make sure you have everything you need before getting started to avoid any delays or complications.

IV. Tips for Printing and Assembling a 3D Printed Wrench Holder

When it comes to 3D printing a wrench holder, there are a few important tips to keep in mind to ensure a successful print and assembly process.

- Choose the right material: Selecting the right material for your wrench holder is crucial. ABS or PLA are commonly used materials for 3D printing, but consider the specific requirements of your wrench holder in terms of strength, durability, and heat resistance.

- Optimize print settings: Adjusting the print settings in your 3D printer is essential for achieving the best results. Pay attention to layer height, infill density, and print speed to strike the right balance between strength and printing time.

- Ensure proper adhesion: To prevent warping or detachment during the printing process, it’s important to ensure proper adhesion of the first layer. Clean the print bed thoroughly, use a heated bed if necessary, and consider using adhesion aids such as a brim or raft.

- Use supports when needed: Depending on the design of your wrench holder, supports may be necessary to print overhangs or bridges successfully. Enable supports in your slicing software and remove them carefully after printing.

- Post-processing: After printing, remove any support structures and use sandpaper or a file to smooth any rough edges or imperfections. This will not only improve the aesthetics but also ensure a better fit for your wrenches.

- Test fit before final assembly: Before fully assembling the wrench holder, make sure to test fit your wrenches to ensure they fit securely and are easily accessible. Make any necessary adjustments or modifications before proceeding.

- Consider additional features: Depending on your specific needs, you may want to add additional features to your wrench holder, such as labels or slots for other tools. Customizing the design to suit your requirements can enhance its functionality.

- Follow assembly instructions: If your wrench holder consists of multiple parts, follow the provided assembly instructions carefully. Pay attention to the order of assembly and ensure all parts are securely attached for a stable and functional wrench holder.

By following these tips, you can confidently 3D print and assemble a wrench holder that meets your needs and keeps your tools organized and easily accessible.

FAQ – 3D Printed Wrench Holder

What is a 3D printed wrench holder?

A 3D printed wrench holder is a tool organizer designed specifically to hold wrenches of various sizes. It is created using a 3D printer, which builds the holder layer by layer using plastic filament.

How does a 3D printed wrench holder work?

The 3D printed wrench holder features individual slots or compartments that are sized to fit different wrenches. Users can simply insert their wrenches into the designated slots, keeping them organized and easily accessible.

What are the advantages of using a 3D printed wrench holder?

Some advantages of using a 3D printed wrench holder include:

1. Organizes wrenches and prevents them from getting misplaced or lost.

2. Allows easy access to the right wrench when needed, saving time and effort.

3. Keeps the workspace tidy and clutter-free.

4. Customizable design options to fit specific wrench sizes and quantities.

5. Cost-effective compared to purchasing pre-made wrench holders.Can I customize the design of a 3D printed wrench holder?

Yes, one of the main advantages of 3D printing is its ability to create customized designs. You can adjust the size, number of slots, and overall layout of the wrench holder to fit your specific needs.

What materials are commonly used for 3D printed wrench holders?

PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) are commonly used materials for 3D printed wrench holders. Both materials are durable and widely available for 3D printing purposes.

Can I use a 3D printed wrench holder for other tools?

While a 3D printed wrench holder is specifically designed for wrenches, it can also be used to store and organize other tools with similar dimensions, such as screwdrivers or pliers.

How do I clean a 3D printed wrench holder?

To clean a 3D printed wrench holder, you can use mild soap and warm water. Gently scrub the holder with a soft brush, rinse it thoroughly, and let it air dry before using it again.

Can I sell or share the 3D printed wrench holder design?

Whether you can sell or share the 3D printed wrench holder design depends on the specific license under which it was created. Some designs may have restrictions, while others may be freely shareable. Always check the license terms before distributing or selling any 3D printed designs.

Can I use any 3D printer to create a wrench holder?

Yes, as long as your 3D printer is capable of printing with the chosen material (e.g., PLA or ABS) and has a large enough build volume to accommodate the size of the wrench holder, you can use any 3D printer to create a wrench holder.

Where can I find 3D printed wrench holder designs?

You can find 3D printed wrench holder designs on various online platforms, such as Thingiverse, MyMiniFactory, or Cults3D. These platforms offer a wide range of free and paid designs created by the 3D printing community.

Conclusion on 3D Printed Wrench Holder

In conclusion, a 3D printed wrench holder is a practical and efficient solution for organizing and storing wrenches. With its customizable design and ability to securely hold multiple wrenches, it is a must-have accessory for any workshop or garage.

By utilizing the power of 3D printing technology, you can easily create a personalized wrench holder that perfectly suits your needs. Say goodbye to the frustration of searching for misplaced wrenches and hello to a more organized and efficient workspace.