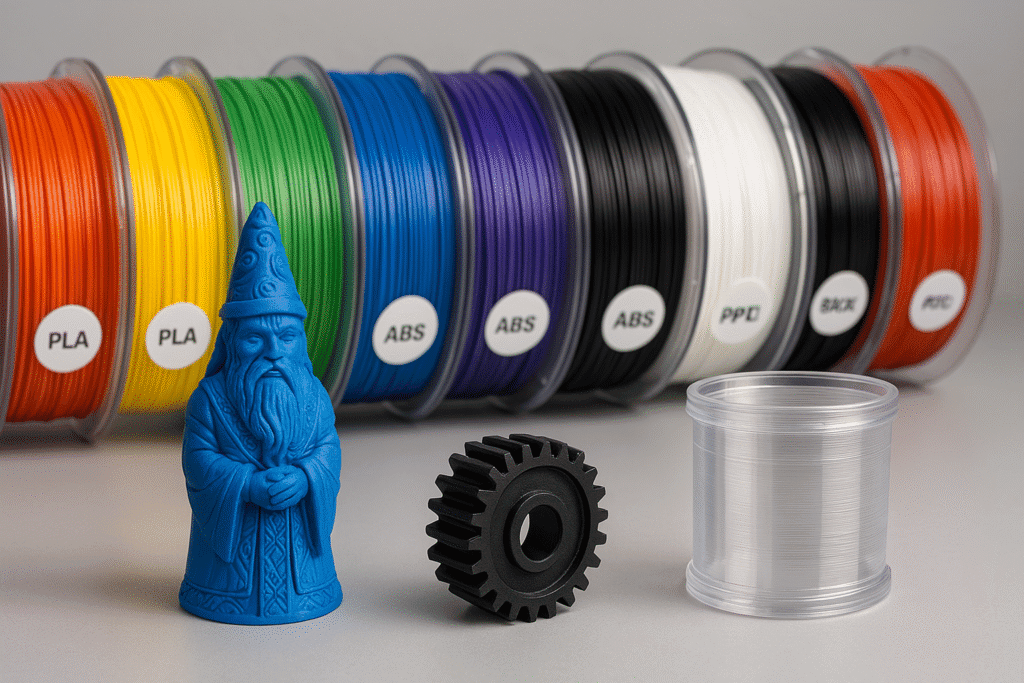

Just as a traditional 2D printer needs ink or toner to create images on paper, your 3D printer relies on filament to bring digital designs into tangible, three-dimensional reality. This seemingly simple strand of plastic (or other material) is the lifeblood of your creations. But not all filaments are created equal. Understanding the different types available is crucial, as your choice directly impacts print quality, strength, flexibility, durability, and even the ease of the printing process itself.

Choosing the wrong filament can lead to frustrating print failures, parts that don’t meet your needs, or even damage to your printer. Conversely, selecting the right material can unlock a world of possibilities, from detailed visual models to robust functional parts.

This comprehensive guide will walk you through the most common 3D printer filament types, helping you understand their properties, pros, cons, and ideal applications. Let’s dive in!

The “Big Three”: Most Common 3D Printer Filaments

For most hobbyists and many professionals, three filament types dominate the landscape: PLA, ABS, and PETG. Let’s break them down.

A. PLA (Polylactic Acid)

- Overview & Key Characteristics: PLA is arguably the most popular 3D printing filament, especially for beginners. It’s a biodegradable thermoplastic derived from renewable resources like cornstarch or sugarcane. Known for its ease of printing, low warping, and pleasant, slightly sweet smell during printing (if any).

- Pros:

- Very easy to print with, forgiving of less-than-perfect printer calibration.

- Minimal warping and shrinking.

- Often doesn’t require a heated print bed (though it helps).

- Available in a vast array of colors and special finishes (e.g., silk, glow-in-the-dark).

- Biodegradable and relatively eco-friendly (under industrial composting conditions).

- Cons:

- Relatively brittle compared to other filaments.

- Low temperature resistance (can deform in a hot car or direct sunlight).

- Can be difficult to post-process (sanding can be tricky, not easily smoothed with solvents).

- Can absorb moisture if not stored properly, leading to print issues.

- Ideal Printing Requirements:

- Nozzle Temperature: 190-220°C

- Bed Temperature: 0-60°C (optional but recommended)

- Enclosure: Not required

- Print Speed: Generally adaptable, can print relatively fast.

- Cooling Fan: Usually 100% after the first few layers.

- Common Applications/Best Uses:

- Visual prototypes and models.

- Figurines, toys, and decorative items.

- Educational tools.

- Items not requiring high strength or heat resistance.

- Post-Processing Notes: Can be sanded (wet sanding is often better), painted with acrylics. Some specialty PLAs can be annealed for increased strength.

B. ABS (Acrylonitrile Butadiene Styrene)

- Overview & Key Characteristics: ABS is a strong, durable, and impact-resistant thermoplastic, the same material LEGO bricks are made from. It offers good heat resistance and is known for its toughness.

- Pros:

- Excellent strength and impact resistance.

- Good heat resistance (higher than PLA).

- Can be easily post-processed (sanding, acetone vapor smoothing for a glossy finish).

- Relatively inexpensive.

- Cons:

- More difficult to print than PLA due to significant warping and shrinking.

- Requires a heated print bed (typically 90-110°C).

- Requires an enclosure to maintain stable ambient temperature and prevent warping/cracking.

- Emits strong fumes (styrene) during printing; good ventilation is essential.

- Not biodegradable and derived from petroleum.

- Ideal Printing Requirements:

- Nozzle Temperature: 230-260°C

- Bed Temperature: 90-110°C

- Enclosure: Highly recommended, almost essential for larger prints.

- Print Speed: Often slower than PLA to manage warping.

- Cooling Fan: Low or off, especially for initial layers, to prevent cracking.

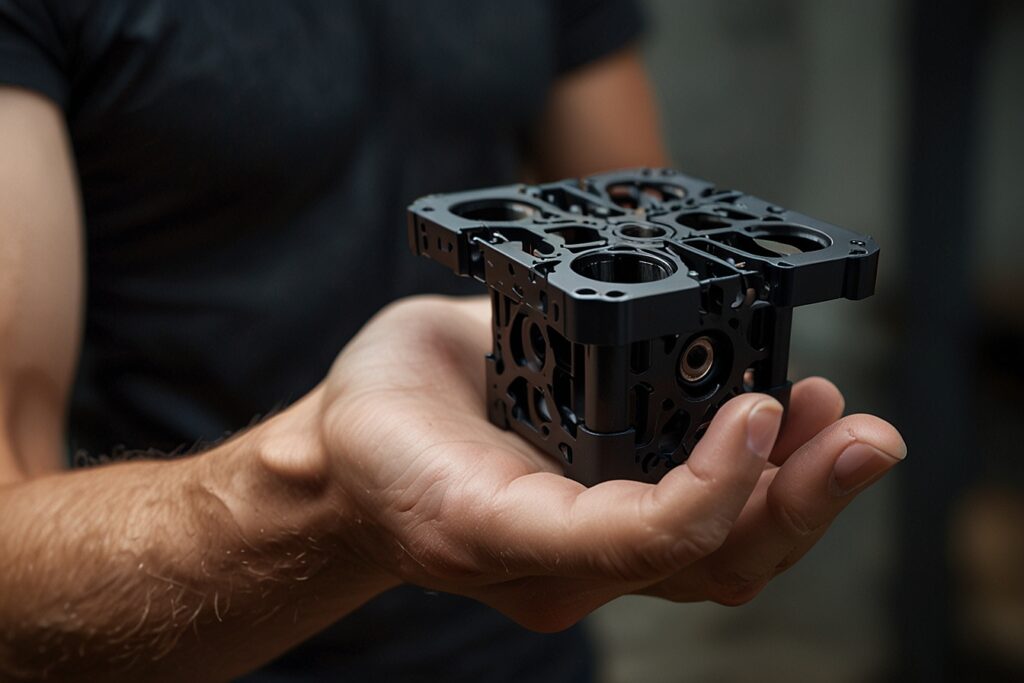

- Common Applications/Best Uses:

- Functional parts requiring strength and durability (e.g., phone cases, drone parts, car components).

- Interlocking parts (like LEGOs).

- Prototypes that need to withstand stress.

- Post-Processing Notes: Sands well. Acetone vapor smoothing can create a very smooth, injection-molded look. Can be easily glued and painted.

C. PETG (Polyethylene Terephthalate Glycol-modified)

- Overview & Key Characteristics: PETG offers a great balance between the ease of printing of PLA and the strength/durability of ABS. It’s known for its excellent layer adhesion, low shrinkage, good chemical resistance, and food-safe properties (check manufacturer specifics).

- Pros:

- Stronger and more durable than PLA.

- More flexible than PLA or ABS (less brittle).

- Excellent layer adhesion.

- Low shrinkage and warping (easier to print than ABS).

- Good chemical resistance.

- Often transparent or translucent options available.

- Can be food-safe (verify with manufacturer and consider printing process).

- Cons:

- Can be prone to stringing and oozing if settings aren’t dialed in.

- Can be more abrasive on brass nozzles over time (consider hardened steel for long-term use).

- Can stick too well to some build surfaces (e.g., glass, PEI); a release agent like glue stick or hairspray might be needed.

- Absorbs moisture more readily than PLA.

- Ideal Printing Requirements:

- Nozzle Temperature: 230-250°C

- Bed Temperature: 70-90°C

- Enclosure: Not strictly required, but can help with consistency for large prints.

- Print Speed: Moderate; too fast can exacerbate stringing.

- Cooling Fan: Moderate (e.g., 30-70%), too much can weaken layer adhesion.

- Common Applications/Best Uses:

- Functional mechanical parts.

- Protective components.

- Food containers (if certified food-safe and printed appropriately).

- Parts needing some flexibility and impact resistance.

- Post-Processing Notes: Can be sanded, though it may “gum up” a bit. Not easily solvent-smoothed.

Quick Comparison: PLA vs. ABS vs. PETG

| Feature | PLA | ABS | PETG |

| Ease of Use | Very Easy | Difficult | Moderate |

| Strength | Moderate | High | High |

| Flexibility | Low (Brittle) | Moderate | Moderate (Less Brittle) |

| Temp. Resist. | Low | High | Moderate |

| Warping | Low | High | Low-Moderate |

| Heated Bed | Optional | Required | Required |

| Enclosure | No | Recommended | Optional |

| Fumes | Low/Sweet | Strong (Ventilation Needed) | Low |

| Common Use | Visual models, prototypes | Functional parts, high-stress applications | Functional parts, food-safe (conditional) |

Exploring Other Popular & Specialty Filaments

Beyond the big three, a fascinating world of specialized filaments awaits!

- A. TPU/TPE (Thermoplastic Polyurethane/Elastomer) – Flexible Filaments

- Characteristics: Rubber-like, flexible, and durable. Available in various hardness levels (Shore hardness).

- Pros: Excellent impact absorption, abrasion resistance.

- Cons: Can be challenging to print (requires slow speeds, specific extruder setups, careful retraction tuning to avoid jamming).

- Uses: Flexible phone cases, RC car tires, seals, wearable items.

- Printing: Slow print speeds, direct drive extruders generally perform better.

- B. Nylon (Polyamide)

- Characteristics: Incredibly strong, durable, and flexible with excellent abrasion resistance.

- Pros: High strength-to-weight ratio, good chemical resistance.

- Cons: Highly hygroscopic (absorbs moisture VERY easily, needs drying before printing and proper storage), can warp, requires high nozzle temperatures.

- Uses: Living hinges, gears, tools, functional parts needing toughness.

- Printing: High nozzle temp (240-270°C+), heated bed, enclosure often helps. Must be kept dry.

- C. PC (Polycarbonate)

- Characteristics: Extremely strong, impact-resistant, and temperature-resistant. Often transparent.

- Pros: One of the strongest consumer 3D printing materials.

- Cons: Very difficult to print (requires very high nozzle and bed temps, prone to warping), highly hygroscopic.

- Uses: Engineering parts, protective gear, high-temp applications.

- Printing: Very high temps (Nozzle: 260-310°C, Bed: 110°C+), robust all-metal hotend needed, enclosure essential.

- D. ASA (Acrylonitrile Styrene Acrylate)

- Characteristics: Similar properties to ABS but with superior UV resistance and weatherability.

- Pros: Strong, good heat resistance, excellent for outdoor applications.

- Cons: Similar printing challenges to ABS (warping, fumes, needs heated bed and enclosure).

- Uses: Outdoor fixtures, automotive exterior parts, garden equipment.

- Printing: Similar to ABS, good ventilation is key.

- E. Wood-Filled Filaments

- Characteristics: PLA-based filament mixed with fine wood particles (e.g., bamboo, cork, pine).

- Pros: Creates prints with a wood-like appearance and texture, can be sanded and stained.

- Cons: Can be more abrasive on nozzles (consider a 0.5mm or larger hardened nozzle), slightly more brittle than standard PLA.

- Uses: Decorative items, models aiming for a wood aesthetic.

- Printing: Similar to PLA, slightly higher temps might be needed. Avoid small nozzle sizes.

- F. Metal-Filled Filaments

- Characteristics: PLA or ABS base mixed with fine metal powders (e.g., bronze, copper, stainless steel).

- Pros: Heavier prints with a metallic look and feel, can be polished for shine.

- Cons: Highly abrasive (hardened steel nozzle essential), can be brittle, expensive. Some require post-processing (sintering) for true metal properties.

- Uses: Statues, jewelry, decorative items, parts where weight is desired.

- Printing: Often requires specific settings, slower speeds.

- G. Carbon Fiber-Filled Filaments

- Characteristics: Base material (PLA, PETG, Nylon, etc.) reinforced with chopped carbon fibers.

- Pros: Significantly increases stiffness and strength, good dimensional stability.

- Cons: Very abrasive (hardened steel nozzle absolutely essential), can increase brittleness in some cases.

- Uses: High-strength functional parts, drone frames, automotive components, jigs.

- Printing: Follow base material guidelines, but expect higher stiffness.

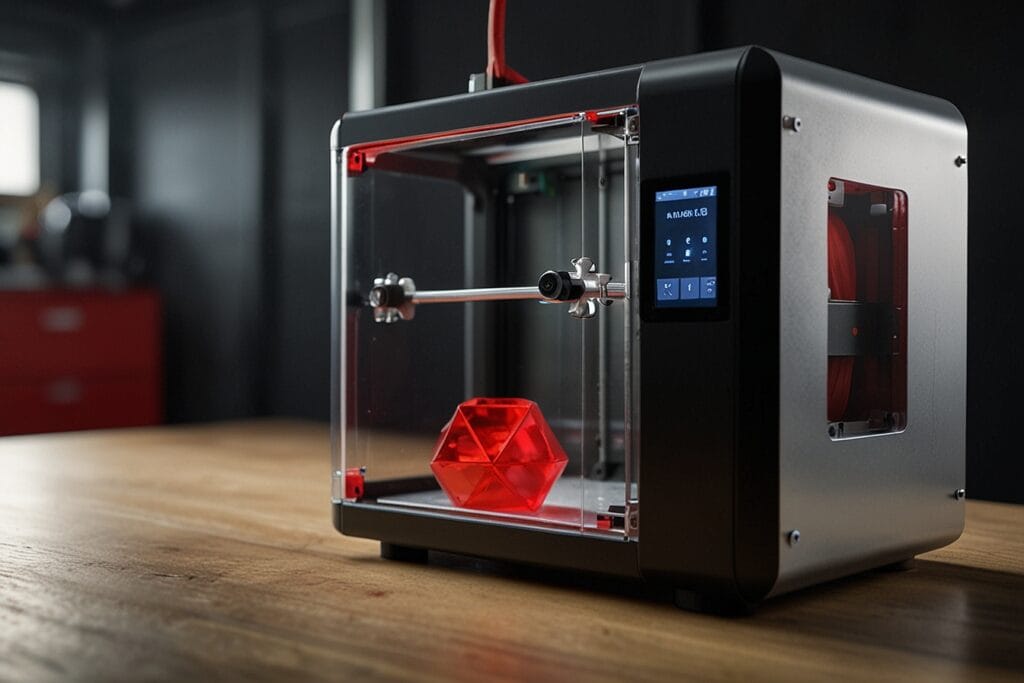

How to Choose the Right Filament for Your Project

With so many options, how do you pick? Ask yourself these questions:

- What is the intended use? Is it a visual model, a functional prototype, or an end-use part?

- What mechanical properties are needed? Does it need to be strong, flexible, heat-resistant, UV-resistant, or impact-resistant?

- What are your printer’s capabilities? Does it have a heated bed? An all-metal hotend? An enclosure? Some filaments have demanding requirements.

- What’s your experience level? Beginners should start with easier filaments like PLA before tackling ABS or Nylon.

- What’s your budget? Specialty filaments can be significantly more expensive.

General Tips:

- Beginners: Start with PLA. It’s forgiving and will help you learn your printer.

- Functional Parts: PETG is often a great all-rounder. If you need more heat resistance or the ability to solvent-smooth, and your printer is capable, ABS (with an enclosure) is an option. Nylon or PC for extreme strength if your printer can handle them.

- Outdoor Use: ASA is your best bet.

- Flexible Parts: TPU/TPE.

- Don’t be afraid to experiment (safely)! Once you’re comfortable, try small test prints with new materials.

Essential Tips for Storing and Handling Filament

- The Enemy: Moisture! Most 3D printing filaments are hygroscopic, meaning they absorb moisture from the air. This can lead to poor print quality (bubbles, stringing, weak parts, nozzle clogs). PLA and PETG are moderately hygroscopic, while Nylon and PC are extremely so.

- Proper Storage: Store filament in airtight containers or resealable bags with desiccant packs (the little silica gel packets) when not in use.

- Drying Filament: If your filament gets “wet,” you may need to dry it. Specialized filament dryers are available, or you can (very carefully!) use an oven on its lowest setting (ensure it can hold a stable, low temperature – usually 40-65°C depending on the material, for several hours). Always research safe drying procedures for your specific filament type before attempting.

- Avoiding Tangles: Ensure the filament is always wound neatly on the spool and secure the loose end when not loaded in the printer to prevent it from unwinding and tangling.

Safety Considerations When Printing

- Ventilation: Always print in a well-ventilated area, especially with materials like ABS, ASA, and Nylon, which can release Volatile Organic Compounds (VOCs) and unpleasant odors. An enclosure vented to the outside is ideal.

- Enclosures: Besides helping with print quality for materials like ABS, an enclosure can also help contain fumes.

- Handling Hot Components: The nozzle and print bed get very hot. Be careful!

- Burns: Keep a safe distance from the hotend and heated bed during operation.

- Fumes from Specific Materials: Some materials, like resin in SLA/DLP printers (not covered in this FDM filament guide), have more significant fume concerns and require careful handling and PPE.

FAQ (Frequently Asked Questions)

Q1: What is the easiest filament for beginners?

A: PLA (Polylactic Acid) is widely considered the easiest filament for beginners due to its low warping, minimal odor, and general forgiveness in printing.

Q2: Can I use any filament with any 3D printer?

A: Not necessarily. Some filaments require high nozzle temperatures that entry-level printers with PTFE-lined hotends can’t safely reach. Others require a heated bed or an enclosure, which not all printers have. Always check your printer’s specifications and the filament’s requirements.

Q3: Is 3D printer filament food safe?

A: This is nuanced. Some filaments like natural PETG or specific PLAs are marketed as “food-safe” material. However, the FDM 3D printing process itself creates layer lines where bacteria can accumulate. Also, brass nozzles can contain small amounts of lead. For true food safety, the printed object typically needs a food-safe coating, or you should use certified food-safe filament with a stainless steel nozzle and print settings designed to minimize gaps. Always verify with the filament manufacturer.

Q4: How much does 3D printer filament cost?

A: Standard PLA and ABS usually range from 15−15−30 per 1kg spool. PETG is often in a similar or slightly higher range. Specialty filaments like Nylon, PC, TPU, and filled filaments (wood, metal, carbon fiber) can cost significantly more, from $30 to $100+ per kg.

Q5: Where is the best place to buy 3D printer filament?

A: Many reputable online retailers specialize in 3D printing supplies (e.g., Amazon, MatterHackers, PrintedSolid, local 3D printing stores). Look for brands with good reviews and consistent quality.

Conclusion: Your Filament Journey Begins

Understanding 3D printer filament types is a cornerstone of successful 3D printing. While PLA is a fantastic starting point, exploring other materials opens up a vast range of applications and possibilities. Each filament has its own personality, quirks, and strengths.

Don’t be intimidated! Start with the basics, learn your printer, and gradually experiment with new materials as your skills and needs grow. The world of 3D printing is constantly evolving, with new and improved filaments appearing regularly.

What’s your favorite filament to print with and why? Or what filament are you curious to try next? Share your experiences and questions in the comments below!