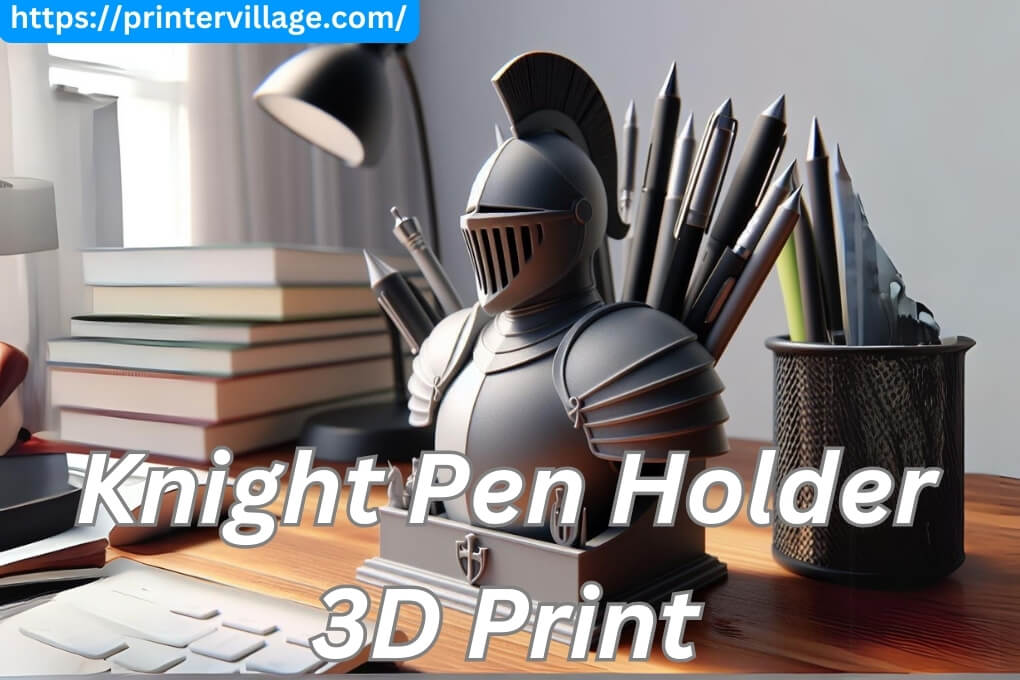

The Knight Pen Holder is a 3D printed accessory that combines functionality with a touch of medieval charm.

The Knight Pen Holder is a unique and practical item that adds a touch of medieval charm to any desk or workspace. With its intricate details and functional design, this 3D printed pen holder is both a conversation starter and a useful tool for keeping pens and pencils organized. Whether you’re a fan of knights and medieval history or simply looking for a creative way to store your writing utensils, the Knight Pen Holder is sure to impress.

I. Benefits of 3D Printing

3D printing has revolutionized the way we create and manufacture objects. With its endless possibilities and numerous advantages, it has gained popularity in various industries.

Here are some of the key benefits of 3D printing:

1. Cost-Effective

Traditional manufacturing methods often involve high costs, especially when it comes to producing complex or customized designs. 3D printing eliminates the need for expensive molds or tools, making it a more cost-effective solution. It allows for on-demand production, reducing inventory costs and waste.

2. Customization

One of the most significant advantages of 3D printing is its ability to create highly customized objects. Whether it’s a personalized phone case or a complex medical implant, 3D printing enables the production of unique designs tailored to specific requirements. This level of customization opens up new possibilities for innovation and creativity.

3. Faster Prototyping

3D printing allows for rapid prototyping, significantly speeding up the product development process. Design iterations can be quickly tested and refined, reducing the time it takes to bring a product to market. This accelerated timeline gives businesses a competitive edge and enables them to stay ahead in a fast-paced market.

4. Complexity and Versatility

Unlike traditional manufacturing methods, 3D printing can produce highly complex geometries and intricate designs with ease. It allows for the creation of objects with internal structures, movable parts, and intricate details that would be challenging or impossible to achieve through other means. Additionally, 3D printing can work with a wide range of materials, including plastics, metals, ceramics, and even food.

5. Sustainability

3D printing has the potential to reduce waste and environmental impact. By only using the necessary amount of material for each object, it minimizes material wastage. Additionally, 3D printing can enable the production of objects using recycled or biodegradable materials, further contributing to a more sustainable manufacturing process.

In conclusion, 3D printing offers numerous benefits that can revolutionize the way we create, design, and manufacture objects. From cost savings to customization and sustainability, this technology has the potential to transform various industries and drive innovation.

II. Introduction to Knight Pen Holder

Are you tired of losing your pens and pencils on your desk? Look no further! The Knight Pen Holder is a stylish and functional accessory that will keep your writing tools organized and easily accessible. This unique pen holder is designed in the shape of a knight, adding a touch of medieval charm to your workspace.

With its intricate details and sturdy construction, the Knight Pen Holder is not only a practical solution but also a decorative piece that will enhance the aesthetics of your desk. Whether you are a student, a professional, or simply someone who loves stationery, this pen holder is a must-have item.

III. How to 3D Print a Knight Pen Holder

Are you ready to bring your 3D printing skills to the next level? In this section, I will guide you through the process of 3D printing a Knight Pen Holder using your own 3D printer. Follow these step-by-step instructions to create a unique and functional pen holder that will impress everyone.

Materials Needed:

- 3D printer

- PLA filament

- 3D modeling software

- Knight Pen Holder STL file (available for download from various online platforms)

- Computer with USB connection

Step 1: Prepare the 3D Model

The first step is to download the Knight Pen Holder STL file from a reliable source. Ensure that the file is compatible with your 3D printer. If necessary, use 3D modeling software to make any modifications or customizations to the design.

Step 2: Slice the Model

Using slicing software, import the STL file and adjust the settings according to your preference. Pay attention to parameters such as layer height, print speed, and infill density. These settings will affect the final quality and strength of your printed Knight Pen Holder.

Step 3: Preheat the 3D Printer

Before starting the printing process, preheat your 3D printer to the recommended temperature for the PLA filament. This will ensure optimal printing conditions and help prevent issues such as warping or poor adhesion.

Step 4: Load the Filament

Insert the PLA filament into the 3D printer’s filament feeder. Make sure the filament is properly inserted and secured to avoid any interruptions during the printing process.

Step 5: Start the Printing Process

Connect your computer to the 3D printer using a USB cable. Open the slicing software and send the sliced model to the printer. Start the printing process and monitor it closely to ensure everything is running smoothly.

Step 6: Remove the Printed Knight Pen Holder

Once the printing is complete, carefully remove the Knight Pen Holder from the printer’s build plate. Use a spatula or scraper to gently detach the printed object, being cautious not to damage it in the process.

Step 7: Post-Processing

Inspect the printed Knight Pen Holder for any imperfections or rough edges. Use sandpaper or a file to smooth out any rough areas and achieve a polished finish. Additionally, you can paint or add any other desired finishing touches to personalize your pen holder.

Step 8: Enjoy Your 3D Printed Knight Pen Holder

Congratulations! You have successfully 3D printed a Knight Pen Holder. Place your favorite pen or pencil in the holder and proudly display it on your desk or give it as a unique gift to someone special.

Tips and Tricks for Successful 3D Printing:

- Ensure your 3D printer is properly calibrated for accurate prints.

- Use high-quality PLA filament for better results.

- Keep your 3D printer’s nozzle clean to prevent clogs.

- Experiment with different print settings to find the optimal balance between speed and quality.

- Always monitor the printing process to address any issues promptly.

| Pros | Cons |

|---|---|

| Allows for customization and personalization | Requires initial investment in a 3D printer and materials |

| Enables rapid prototyping and iteration | May have limitations in terms of size and complexity |

| Reduces waste by only printing what is needed | Print times can be lengthy depending on the design |

IV. Tips and Tricks for Successful 3D Printing

When it comes to 3D printing, there are a few tips and tricks that can help ensure a successful print. Here are some important factors to consider:

1. Choose the right filament

Using the right filament is crucial for a successful 3D print. Different filaments have different properties, such as strength, flexibility, and temperature resistance. Make sure to choose a filament that is suitable for your specific project.

2. Calibrate your printer

Proper calibration of your 3D printer is essential for achieving accurate prints. This includes calibrating the bed level, nozzle height, and extrusion rate. Take the time to calibrate your printer before each print to ensure optimal results.

3. Use supports when necessary

For complex or overhanging designs, using supports can help prevent sagging or collapsing during the printing process. Supports are temporary structures that provide additional stability for intricate parts of the print. Be sure to check your slicing software to enable supports if needed.

4. Optimize print settings

Adjusting print settings can greatly impact the quality of your 3D prints. Parameters such as layer height, print speed, and infill density can be adjusted to achieve the desired balance between print time and quality. Experiment with different settings to find the optimal configuration for your project.

5. Maintain proper cooling

Heat can affect the quality of your 3D prints, especially for small or intricate parts. Ensure that your printer has adequate cooling, either through a built-in fan or external cooling methods. This will help prevent warping or distortion during the printing process.

6. Clean and maintain your printer

Regular cleaning and maintenance of your 3D printer is important to keep it running smoothly. This includes removing any debris or filament residue from the print bed, lubricating moving parts, and checking for any loose screws or belts. A well-maintained printer is more likely to produce consistent and high-quality prints.

7. Learn from failed prints

Don’t be discouraged by failed prints; instead, use them as learning opportunities. Analyze what went wrong and try to identify the root cause. Whether it’s a design issue, improper settings, or a mechanical problem, understanding the cause of failure can help you improve your future prints.

8. Post-processing and finishing touches

After the print is complete, you may need to perform some post-processing to achieve the desired final result. This can include sanding, painting, or adding additional components. Take your time to carefully finish your print to achieve the desired aesthetic or functional outcome.

| Tips | Description |

|---|---|

| Choose the right filament | Select a filament that suits your project’s requirements |

| Calibrate your printer | Ensure accurate prints by calibrating bed level, nozzle height, and extrusion rate |

| Use supports when necessary | Add temporary supports for complex or overhanging designs |

| Optimize print settings | Adjust parameters to achieve the desired balance between print time and quality |

| Maintain proper cooling | Prevent warping or distortion by ensuring adequate cooling |

| Clean and maintain your printer | Regularly clean and maintain your printer for consistent and high-quality prints |

| Learn from failed prints | Analyze failures to improve future prints |

| Post-processing and finishing touches | Perform necessary post-processing to achieve desired final result |

Frequently Asked Questions For Knight Pen Holder 3D Print

What is a Knight Pen Holder 3D Print?

A Knight Pen Holder 3D Print is a 3D-printed pen holder designed in the shape of a knight, typically made from durable materials like PLA or ABS plastic.

How does the Knight Pen Holder 3D Print work?

The Knight Pen Holder 3D Print is designed to hold pens, pencils, or other writing utensils. Simply insert your pen into the designated slot on the knight’s back, and it will securely hold your pen in an upright position.

Can I use the Knight Pen Holder 3D Print for other purposes?

While the primary purpose of the Knight Pen Holder 3D Print is to hold pens, it can also be used as a decorative item or even a small figurine.

Is the Knight Pen Holder 3D Print customizable?

Yes, the Knight Pen Holder 3D Print can be customized according to your preferences. You can choose different colors, sizes, and even add personalized engravings or logos.

Can I 3D print the Knight Pen Holder myself?

Yes, if you have access to a 3D printer, you can download the design files for the Knight Pen Holder and print it yourself. There are various websites and online communities where you can find the necessary files.

What materials are commonly used for 3D printing the Knight Pen Holder?

The Knight Pen Holder is often printed using PLA (polylactic acid) or ABS (acrylonitrile butadiene styrene) plastic. These materials are popular due to their durability and ease of printing.

Is the Knight Pen Holder 3D Print suitable for all pen sizes?

The Knight Pen Holder is designed to accommodate standard-sized pens and pencils. However, some variations may allow for larger or smaller pens. It is advisable to check the specifications before purchasing or printing.

How do I clean the Knight Pen Holder 3D Print?

You can clean the Knight Pen Holder by gently wiping it with a damp cloth. Avoid using harsh chemicals or abrasive materials, as they may damage the surface of the print.

Can I purchase a pre-printed Knight Pen Holder?

Yes, there are many online marketplaces and specialty stores that offer pre-printed Knight Pen Holders. You can choose from a variety of designs and colors to suit your preferences.

How can I get the Knight Pen Holder 3D Print?

If you don’t have access to a 3D printer, you can purchase the Knight Pen Holder from various online retailers or local stores specializing in 3D-printed products. Simply search for “Knight Pen Holder 3D Print” and explore the available options.

Conclusion On Knight Pen Holder 3D Print

With its sleek design and practical functionality, the Knight Pen Holder 3D Print is a must-have accessory for any office or workspace. Made with high-quality materials and precision 3D printing technology, this pen holder is not only a stylish addition to your desk but also a convenient way to keep your writing tools organized. Say goodbye to clutter and hello to efficiency with the Knight Pen Holder 3D Print.