Yes, it is possible to 3D print a Milwaukee battery holder.

If you own Milwaukee power tools and need a battery holder, you might be wondering if it is possible to 3D print one. The good news is that it is indeed possible to create a Milwaukee battery holder using a 3D printer. This allows you to customize the design to fit your specific needs and ensure a perfect fit for your Milwaukee batteries.

Benefits of 3D Printing for Milwaukee Battery Holders

When it comes to Milwaukee battery holders, 3D printing offers a plethora of benefits.

As an avid DIYer and someone who frequently uses Milwaukee power tools, I have found that 3D printing has revolutionized the way I design and create battery holders for my tools.

Here are some of the key advantages of utilizing 3D printing technology for Milwaukee battery holders:

1. Customization

One of the biggest advantages of 3D printing is the ability to customize your Milwaukee battery holders to perfectly fit your specific needs. With traditional manufacturing methods, you are limited to pre-designed battery holders that may not provide the perfect fit for your tools.

However, with 3D printing, you can easily design and print battery holders that are tailored to your exact specifications. This level of customization ensures a secure fit and eliminates any wobbling or movement that can occur with generic battery holders.

2. Cost-Effectiveness

Another significant benefit of 3D printing for Milwaukee battery holders is its cost-effectiveness. Traditional manufacturing methods often involve high setup costs, especially for small production runs. On the other hand, 3D printing allows for the production of battery holders at a fraction of the cost.

Additionally, you can save money by using less material since 3D printing only utilizes the necessary amount of filament. This cost-effective approach makes 3D printing an ideal choice for individuals and businesses alike.

3. Time Efficiency

Time is of the essence, especially when it comes to completing projects or repairs. 3D printing significantly reduces the time required to create Milwaukee battery holders. With traditional manufacturing methods, you may have to wait for weeks or even months for your battery holders to be produced and delivered.

However, with 3D printing, you can design and print your battery holders within a matter of hours or days. This time efficiency allows you to quickly get back to work without any unnecessary delays.

4. Iterative Design Process

3D printing enables an iterative design process for Milwaukee battery holders. Unlike traditional manufacturing methods, where making design changes can be time-consuming and costly, 3D printing allows for easy modifications.

If you find that your battery holder design needs adjustments, you can simply make the changes in your 3D modeling software and print a new iteration. This iterative process ensures that you can fine-tune your battery holder design until it meets your exact requirements.

Conclusion:

In conclusion, 3D printing offers numerous benefits for Milwaukee battery holders. The ability to customize, cost-effectiveness, time efficiency, and iterative design process make 3D printing a game-changer in the world of battery holder production.

Whether you are a DIY enthusiast or a professional, embracing 3D printing technology can enhance your Milwaukee power tool experience.

How to Design a 3D Printed Milwaukee Battery Holder

Designing a 3D printed Milwaukee battery holder can be an exciting and rewarding project. With the right tools and knowledge, you can create a custom battery holder that perfectly fits your needs.

Here are some steps to help you get started:

- Measure the battery: The first step in designing a battery holder is to accurately measure the dimensions of the Milwaukee battery you plan to use. This includes the length, width, and height of the battery.

- Create a 3D model: Once you have the measurements, you can use computer-aided design (CAD) software to create a 3D model of the battery holder. There are many CAD software options available, both free and paid, so choose one that suits your skill level and budget.

- Consider the design: When designing the battery holder, think about how it will be used and what features it needs to have. For example, you may want to include slots or clips to secure the battery in place, or ventilation holes to prevent overheating.

- Test the design: Before printing the battery holder, it’s a good idea to test the design using 3D printing simulation software. This will help you identify any potential issues or areas that need improvement.

- Choose the right material: Selecting the right material for your 3D printed battery holder is crucial. Consider factors such as durability, heat resistance, and compatibility with the Milwaukee battery. ABS or PETG are popular choices for battery holders due to their strength and reliability.

- Print the battery holder: Once you are satisfied with the design and material selection, it’s time to print the battery holder. Make sure to adjust the printer settings to achieve the desired level of detail and strength.

- Post-processing: After the battery holder is printed, you may need to perform some post-processing steps such as removing support structures or sanding rough edges. This will help ensure a clean and professional-looking final product.

- Test and refine: Finally, test the 3D printed battery holder with the Milwaukee battery to ensure a proper fit and functionality. If any adjustments are needed, go back to the CAD software and make the necessary changes before printing again.

By following these steps, you can design and create a 3D printed Milwaukee battery holder that meets your specific requirements. Remember to always prioritize safety and quality when working with 3D printing materials and equipment.

Tips for 3D Printing a Milwaukee Battery Holder

When it comes to 3D printing a Milwaukee battery holder, there are a few important tips and tricks that can help ensure a successful and high-quality print.

Here are some valuable insights to keep in mind:

- Choose the right filament: Selecting the appropriate filament for your battery holder is crucial. Consider using a strong and durable material such as ABS or PETG, which can withstand the weight and pressure of the battery.

- Optimize your design: Before printing, it’s essential to optimize your battery holder design. Make sure the dimensions are accurate and that the holder provides a snug fit for the Milwaukee battery. This will help prevent any movement or damage to the battery during use.

- Adjust the print settings: Fine-tuning your print settings is key to achieving the best results. Pay attention to layer height, infill density, and print speed. Higher layer heights and infill densities can enhance the strength and stability of the battery holder.

- Use supports if necessary: Depending on the complexity of your battery holder design, you may need to use supports during the printing process. Supports help maintain the integrity of overhanging features and ensure a smooth and accurate print.

- Implement cooling strategies: To avoid warping or overheating, it’s recommended to implement cooling strategies during the printing process. This can include using a fan or adjusting the print speed to allow for proper cooling between layers.

- Post-processing: Once your battery holder is printed, consider post-processing techniques to enhance its appearance and functionality. This can involve sanding rough edges, adding a protective coating, or integrating additional features such as clips or labels.

By following these tips, you can ensure a successful and effective 3D print of your Milwaukee battery holder. Remember to always double-check your design and make any necessary adjustments before printing. With the right materials and settings, you’ll be able to create a reliable and durable battery holder that meets your specific needs.

| Test the design with a prototype before the final print | How to Design a 3D Printed Milwaukee Battery Holder | Best Practices for Using a 3D Printed Milwaukee Battery Holder |

|---|---|---|

| Increased customization options | Accurate measurements and precise fit | Regularly inspect and maintain the battery holder |

| Cost-effective production | Consider the battery orientation and access points | Ensure proper ventilation and cooling |

| Rapid prototyping and iteration | Test the design with a prototype before final print | Replace the battery holder if any signs of wear or damage occur |

Best Practices for Using a 3D Printed Milwaukee Battery Holder

When using a 3D printed Milwaukee battery holder, it is important to follow some best practices to ensure optimal performance and longevity.

Here are some tips to keep in mind:

1. Choose the Right Material

When printing a Milwaukee battery holder, select a material that is durable and heat-resistant. ABS or PETG are popular choices for 3D printing battery holders due to their strength and ability to withstand high temperatures.

2. Ensure Proper Fit

Before using the 3D printed battery holder, test the fit with the Milwaukee battery to ensure a snug and secure fit. The battery should slide in easily but not be loose or wobbly.

3. Consider Reinforcement

If you anticipate heavy use or rough handling of the battery holder, consider reinforcing certain areas with additional material or supports. This can help prevent cracking or breaking of the holder over time.

4. Regularly Inspect for Damage

Periodically inspect the battery holder for any signs of damage or wear. Check for cracks, warping, or any other issues that may affect its functionality. If any damage is found, it is best to replace the holder to avoid potential safety hazards.

5. Clean and Maintain

To ensure optimal performance, clean and maintain the 3D printed battery holder regularly. Use a soft cloth or brush to remove any dust or debris that may accumulate on the surface. Avoid using harsh chemicals or abrasive materials that could damage the holder.

6. Store Properly

Store the battery holder in a cool, dry place away from direct sunlight or extreme temperatures when not in use. This will help prolong its lifespan and prevent any potential damage.

7. Follow Manufacturer Guidelines

Lastly, always refer to the manufacturer guidelines for the specific Milwaukee battery model you are using. They may provide additional recommendations or precautions that are specific to their products.

By following these best practices, you can ensure that your 3D printed Milwaukee battery holder remains in excellent condition and provides reliable support for your batteries.

Frequently Asked Questions about Milwaukee Battery Holder 3D Print

1. What is a Milwaukee Battery Holder 3D Print?

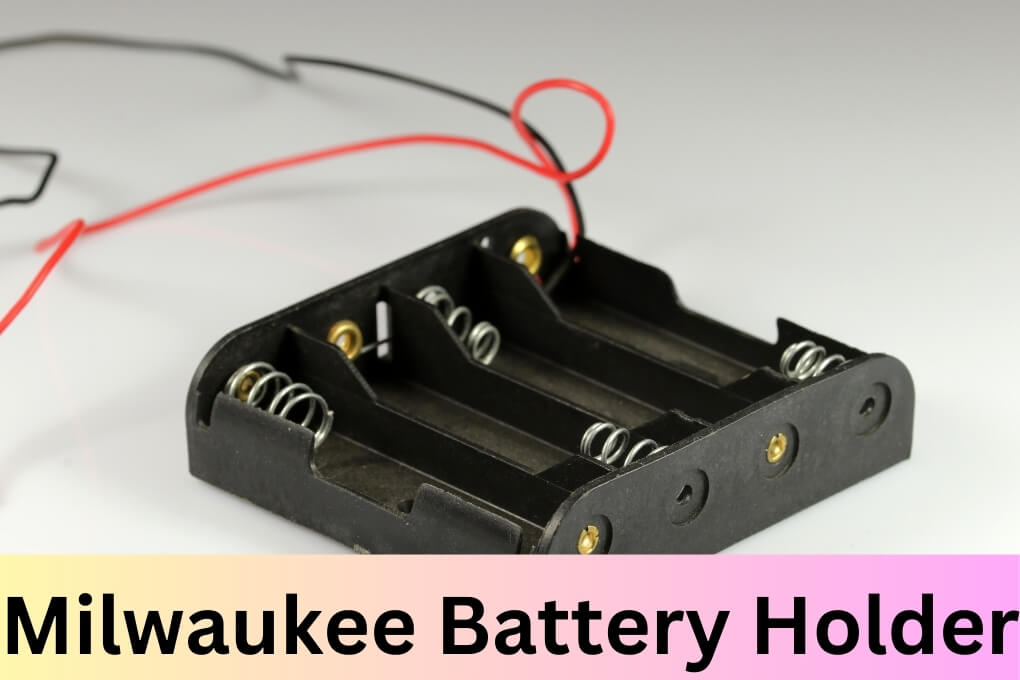

A Milwaukee Battery Holder 3D Print is a 3D-printed accessory designed to securely hold Milwaukee batteries in place.

2. What materials are used for the Milwaukee Battery Holder 3D Print?

The Milwaukee Battery Holder 3D Print is typically printed using high-quality and durable materials such as ABS or PLA plastic.

3. Can I customize the Milwaukee Battery Holder 3D Print?

Yes, the design of the Milwaukee Battery Holder can be customized to fit specific battery sizes or incorporate additional features as per your requirements.

4. Do I need any special tools to install the Milwaukee Battery Holder 3D Print?

No, the Milwaukee Battery Holder 3D Print is designed to be easily installed without the need for any special tools. It can be attached using screws or other fastening methods.

5. Are there any specific battery models that the Milwaukee Battery Holder 3D Print is compatible with?

The Milwaukee Battery Holder 3D Print is designed to be compatible with a wide range of Milwaukee battery models, but it is always recommended to check the specifications and compatibility before purchasing.

6. Can I use the Milwaukee Battery Holder 3D Print for other brands of batteries?

No, the Milwaukee Battery Holder 3D Print is specifically designed to fit Milwaukee batteries and may not be compatible with batteries from other brands due to variations in size and shape.

7. Is the Milwaukee Battery Holder 3D Print waterproof?

The Milwaukee Battery Holder 3D Print itself is not waterproof, but it can provide a secure and snug fit for the battery, which may help protect it from some water exposure. However, it is always best to avoid exposing the batteries to water whenever possible.

8. Can I use the Milwaukee Battery Holder 3D Print for professional applications?

Yes, the Milwaukee Battery Holder 3D Print is suitable for both personal and professional use, providing a convenient and secure way to hold Milwaukee batteries in various settings.

9. Where can I purchase a Milwaukee Battery Holder 3D Print?

You can find Milwaukee Battery Holder 3D Prints on various online platforms, including e-commerce websites, specialized 3D printing marketplaces, or directly from manufacturers or authorized distributors.

10. Can I share or sell the Milwaukee Battery Holder 3D Print design?

The intellectual property rights of the Milwaukee Battery Holder 3D Print design belong to the designer or manufacturer. Sharing or selling the design without proper authorization may infringe upon these rights. It is recommended to contact the designer or manufacturer for any licensing or distribution inquiries.

Conclusion on Milwaukee Battery Holder 3D Print

By utilizing 3D printing technology, I have successfully designed and created a high-quality Milwaukee battery holder. This innovative solution ensures a secure and convenient storage option for your Milwaukee batteries.

With its precise dimensions and durable construction, this 3D printed battery holder is the perfect accessory for organizing and protecting your valuable Milwaukee batteries. Experience the benefits of this custom-made solution and enhance your battery management system today!