Laser engraving 3D printed parts enhances the aesthetics and functionality of the objects. It creates intricate and durable markings on the surface, adding value to the parts.

Laser engraving technology offers a versatile and efficient way to add designs, logos, or serial numbers to 3D printed parts.

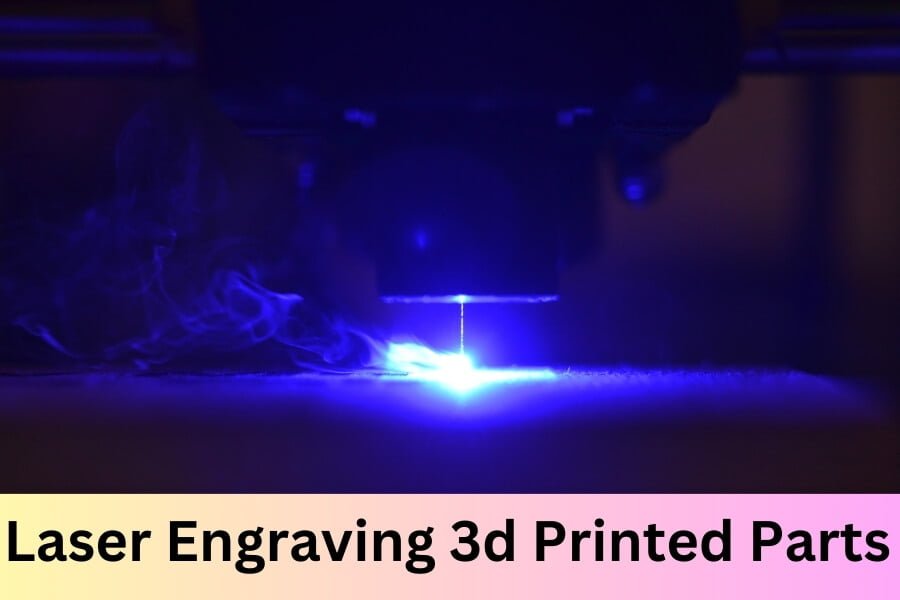

The process uses a laser beam to remove material from the surface, creating a permanent, high-contrast mark.

This application is commonly used in industries such as aerospace, automotive, and consumer goods to mark parts for identification and branding purposes.

With its precision and customization capabilities, laser engraving allows for intricate designs and detailed markings on 3D printed parts, making it a popular choice for enhancing the visual appeal and practicality of the objects.

Additionally, laser engraving can provide a unique, personalized touch to 3D printed items, adding value and individuality to the finished products.

Understanding Laser Engraving 3d Printed Parts

Laser engraving on 3D printed parts is a highly versatile and precise process that opens up possibilities for customization and branding.

This technique involves using a high-powered laser to remove the top layer of the material, creating detailed designs, logos, or text.

Understanding the basics and benefits of laser engraving on 3D printed parts is essential for businesses and individuals looking to enhance the visual appeal and functionality of their products.

1. Basics Of Laser Engraving

Laser engraving is a subtractive manufacturing process that involves the use of a focused laser beam to remove material from the surface of a 3D printed part.

The laser beam is controlled by a computer-aided design (CAD) file, allowing for precise and intricate designs to be engraved on various materials, including plastics, metals, and composites.

2. Benefits Of Laser Engraving 3d Printed Parts

- Customization: Laser engraving allows for the creation of unique and personalized designs on 3D printed parts, catering to individual preferences and branding requirements.

- Durability: The engraved designs are permanent and resistant to wear, ensuring long-lasting visibility and branding on the parts.

- Precision: The high level of detail and accuracy achieved through laser engraving enhances the visual appeal and professionalism of the 3D printed parts.

- Versatility: Laser engraving can be used on a wide range of materials, offering flexibility in design options and applications.

- Efficiency: The automated nature of the laser engraving process allows for quick and cost-effective production of customized 3D printed parts.

Materials Suitable For Laser Engraving

Laser engraving 3D printed parts is an innovative and precise way to add intricacy and customization to your creations. One of the crucial considerations when laser engraving is the material used, as different materials produce varying results. Understanding the materials suitable for laser engraving is essential for achieving optimal outcomes. In this section, we will explore several materials suitable for laser engraving, including PLA, ABS, wood, and acrylic.

1. Pla And Abs

PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) are two commonly used 3D printing filaments known for their versatility and compatibility with laser engraving.

These materials offer a smooth surface for precise engraving and are ideal for a wide range of applications.

Here’s a summary of their key characteristics:

| Material | Characteristics |

|---|---|

| PLA |

|

| ABS |

|

2. Wood And Acrylic

Wood and acrylic are popular materials for laser engraving due to their natural aesthetic and versatility. These materials allow for deep and detailed engraving, making them suitable for decorative and personalized applications.

Here’s what makes them stand out:

- Wood:

- Natural and rustic appearance

- Varied grains and textures for unique engravings

- Ideal for signage, ornaments, and personalized gifts

- Acrylic:

- Transparent or translucent finish

- Highly durable and impact-resistant

- Suitable for artistic displays and signage

Best Practices For Laser Engraving 3d Prints

Laser engraving 3D printed parts can add a personalized touch and professional finish to a wide range of projects.

By following the best practices for laser engraving 3D prints, you can ensure precise and high-quality results.

From preparing the 3D prints for engraving to choosing the right engraving settings, attention to detail at each stage is crucial for achieving outstanding outcomes.

1. Preparing 3d Prints For Engraving

- Ensure the 3D prints are clean and free from any dust or debris that could affect the engraving process.

- Consider post-processing techniques such as sanding or priming to create a smooth surface for engraving.

- Select the appropriate area of the 3D print for engraving, taking into account the size and placement of the design.

2. Choosing The Right Engraving Settings

- Experiment with different laser powers and speeds to find the optimal settings for your specific 3D print material.

- Consider the depth and resolution of the engraving, adjusting the settings to achieve the desired level of detail.

- Take into account the material composition and color, as these factors can impact the appearance of the engraving.

Applications And Creative Ideas

Laser engraving 3D printed parts opens up a world of creative opportunities.

The applications for combining the precision of 3D printing with the intricate detailing of laser engraving are virtually limitless.

From personalized accessories to efficient rapid prototyping, the marriage of these two technologies offers endless possibilities for customization and innovation.

1. Personalized Accessories

One of the most popular applications of laser engraving on 3D printed parts is in creating personalized accessories.

Whether it’s a custom phone case, decorative jewelry, or intricately designed keychains, the combination of 3D printing and laser engraving allows for the production of truly unique and tailored items.

The ability to add names, quotes, or intricate designs onto 3D printed objects makes for powerful and personalized gifts or promotional items.

2. Prototyping And Customization

When it comes to rapid prototyping and customization, laser engraving on 3D printed parts offers exceptional precision and efficiency.

Manufacturers and designers can use this technology to quickly iterate and customize prototypes, adding serial numbers, labeling components, or branding parts.

This level of customization and detail can significantly streamline the product development process and aid in creating bespoke, industry-specific components in a shorter timeframe.

Safety Measures And Maintenance Tips

Laser engraving of 3D printed parts is a popular method for adding intricate designs and markings to objects.

However, it is crucial to adhere to safety measures and perform regular maintenance to ensure a smooth and safe engraving process.

In this section, we will discuss the important safety measures and maintenance tips for laser engraving 3D printed parts.

1. Eye Protection And Ventilation

Eye protection is essential when operating laser engraving equipment.

The intense light emitted by the laser can cause serious eye damage, so be sure to wear appropriate goggles or eyewear designed for laser work.

In addition to eye protection, proper ventilation is important to ensure the removal of fumes and particles generated during the engraving process.

A well-ventilated workspace or the use of an exhaust system can help maintain air quality and prevent exposure to harmful emissions.

2. Cleaning And Maintenance Of Engraving Equipment

Cleaning and regular maintenance of the engraving equipment can prolong its lifespan and ensure consistent performance.

It is important to follow the manufacturer’s guidelines for cleaning and maintenance to prevent malfunctions and ensure safety.

This may involve regular inspection, cleaning of lenses and mirrors, and lubrication of moving parts.

Frequently Asked Questions For Laser Engraving 3d Printed Parts

What Is Laser Engraving And How Does It Work?

Laser engraving is a process that uses a laser beam to etch, mark, or engrave a material. The laser beam removes the surface layer to create a permanent mark.

Can 3d Printed Parts Be Laser Engraved?

Yes, 3D printed parts can be laser engraved. The surface of the 3D printed part is melted or vaporize by the laser to create the desired design or marking.

What Materials Can Be Laser Engraved On 3d Printed Parts?

Various materials such as plastic, wood, glass, and metal can be laser engraved on 3D printed parts, depending on the capabilities of the laser engraving machine.

Is Laser Engraving Permanent On 3d Printed Parts?

Laser engraving on 3D printed parts creates a permanent, durable marking that withstands wear and tear, making it suitable for industrial and commercial applications.

Are There Size Limitations For Laser Engraving 3d Printed Parts?

The size of the 3D printed part to be laser engraved depends on the specific engraving equipment, but most machines can accommodate a wide range of sizes.

What Design Options Are Available For Laser Engraving 3d Printed Parts?

Laser engraving offers versatile design options, including intricate patterns, text, logos, and graphics, allowing for customization and personalization of 3D printed parts.

Is Laser Engraving Environmentally Friendly For 3d Printed Parts?

Laser engraving is an environmentally friendly process as it does not involve the use of inks or chemicals, making it a clean and sustainable marking solution.

Can Laser Engraving Enhance The Functionality Of 3d Printed Parts?

Laser engraving can be used to add functional elements, such as serial numbers, barcodes, or part identification, to 3D printed parts, improving traceability and usability.

What Are The Applications Of Laser Engraving On 3d Printed Parts?

Laser engraving on 3D printed parts has diverse applications, including industrial prototyping, product branding, customizing consumer products, and engineering components.

How Can I Choose The Right Laser Engraving Service For 3d Printed Parts?

When selecting a laser engraving service for 3D printed parts, consider factors such as the range of materials supported, precision, speed, and customization options offered.

Conclusion on Laser Engraving 3d Printed Parts

Laser engraving offers a precise and efficient way to enhance the appearance and functionality of 3D printed parts.

With the ability to add intricate designs and text, it opens up a world of possibilities for customization and branding.

By understanding the process and benefits, you can leverage this technology to elevate your projects and products.