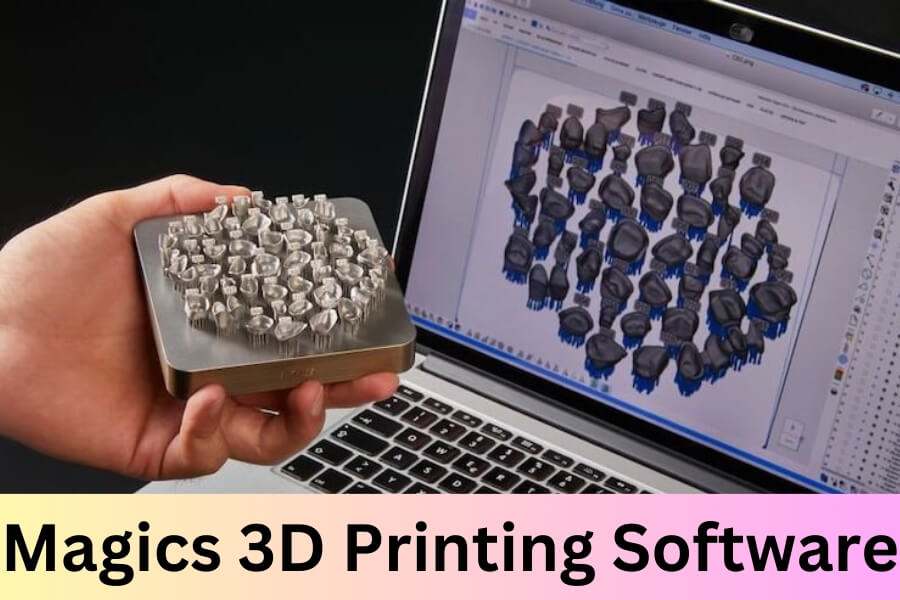

Magics 3D Printing Software is a powerful tool for preparing, optimizing, and repairing 3D models for printing. It offers advanced features for achieving high-quality results in additive manufacturing.

Magics 3D Printing Software is the go-to solution for professionals in the additive manufacturing industry. Its comprehensive set of tools allows users to efficiently prepare, optimize, and repair 3D models for printing, ensuring the highest quality output.

With its user-friendly interface and advanced capabilities, Magics is an indispensable asset for businesses and individuals looking to excel in the world of 3D printing.

Whether it’s for prototyping, production, or other applications, Magics 3D Printing Software delivers the precision and reliability required for success in the additive manufacturing realm.

The Rise Of Magics 3d Printing Software

The rise of Magics 3D printing software has revolutionized the manufacturing and prototyping industry, offering an unparalleled suite of advanced tools and features for creating high-quality 3D printed products.

With its intuitive interface and powerful functionalities, Magics software has become a game-changer in the 3D printing realm, empowering businesses and designers to bring their innovative concepts to life with unparalleled precision and efficiency.

1. The Changing Landscape Of 3d Printing Industry

The 3D printing industry is experiencing a paradigm shift, driven in no small part by the advancements in software technology.

Magics 3D printing software has emerged as a leading force in this changing landscape, enabling professionals to unlock the full potential of additive manufacturing.

Its cutting-edge capabilities have elevated the standards for 3D printing, paving the way for unprecedented creativity and craftsmanship.

2. Historical Development Of Magics Software

Since its inception, Magics software has continuously evolved to meet the evolving needs of the 3D printing community.

Developed by Materialise, a pioneering company in additive manufacturing, Magics has a rich history of innovation and refinement.

From its early iterations to the current state-of-the-art version, the software has set benchmarks for quality, reliability, and versatility, cementing its status as an indispensable tool for every 3D printing enthusiast.

Key Features Of Magics 3d Printing Software

When it comes to 3D printing, having the right software can make all the difference.

Magics 3D Printing Software is a powerful tool that provides a range of key features to streamline the 3D printing process, from file preparation to printing.

Let’s explore some of the standout features that make Magics a popular choice among 3D printing enthusiasts and professionals.

1. Advanced Mesh Editing Tools

Magics 3D Printing Software is equipped with advanced mesh editing tools that allow users to manipulate the 3D models with precision.

From repairing mesh errors to optimizing the model for 3D printing, the software offers a comprehensive set of tools to ensure that the 3D models are print-ready.

Users can easily edit, analyze, and repair meshes, making it an invaluable asset in the 3D printing workflow.

2. Support For Various 3d File Formats

Magics 3D Printing Software supports a wide range of 3D file formats, providing flexibility and compatibility for users working with different 3D design software.

Whether it’s STL, 3MF, or AMF, the software seamlessly handles various file formats, enabling users to import and prepare 3D models for printing without the hassle of format conversion.

3. Integration With 3d Printing Machines

Magics 3D Printing Software offers seamless integration with a variety of 3D printing machines, allowing users to directly interface with their 3D printers.

This integration streamlines the printing workflow, ensuring that 3D models are prepared and sent to the printer with ease. By bridging the gap between software and hardware, Magics delivers a smooth and efficient 3D printing experience.

Applications Of Magics 3d Printing Software

1. Prototyping And Rapid Manufacturing

Magics 3D printing software is widely used in the manufacturing industry for rapid prototyping and production of final parts.

The software provides advanced tools for preparing and optimizing 3D models for additive manufacturing processes, enabling companies to iterate and test designs quickly.

Its features such as repairing, editing, and enhancing 3D designs make it an essential tool for creating prototypes and bringing products to market faster.

2. Customized Medical Implants And Prosthetics

In the healthcare sector, Magics 3D printing software plays a crucial role in creating customized medical implants and prosthetics.

By leveraging the software’s capabilities, medical professionals can design and manufacture patient-specific implants and prosthetic devices tailored to individual anatomical structures.

This personalized approach improves patient outcomes and enhances the overall quality of healthcare delivery.

3. Aerospace And Automotive Component Design

For the aerospace and automotive industries, Magics 3D printing software offers cutting-edge solutions for designing complex components with precision and efficiency.

The software’s support generation and optimization features enable engineers to produce lightweight, high-performance parts that meet the stringent requirements of aerospace and automotive applications.

With Magics, companies can achieve enhanced part functionality and reduced production lead times.

Impact Of Magics 3d Printing Software On Industries

Magics 3D printing software has significantly revolutionized various industries, having a profound impact on the way products are designed, manufactured, and brought to market.

Through its advanced capabilities, Magics software has brought about increased efficiency, innovation in product development and design, and a notable transition towards sustainable manufacturing practices.

1. Increased Efficiency And Cost Savings

The utilization of Magics 3D printing software has had a transformative effect on the efficiency and cost-effectiveness of manufacturing processes.

By streamlining workflows and enabling the seamless optimization of printing designs, Magics software has played an instrumental role in minimizing waste and reducing production time.

This has resulted in substantial cost savings for businesses across various industries.

2. Innovation In Product Development And Design

Magics 3D printing software has sparked a wave of innovation in product development and design, empowering engineers and designers to explore unprecedented design possibilities.

The software’s advanced features and capabilities have enabled the creation of complex, intricate structures and shapes that were previously unattainable.

This has led to the development of innovative products with enhanced functionality and aesthetic appeal, driving significant competitive advantage for organizations.

3. Transition Towards Sustainable Manufacturing

A significant impact of Magics 3D printing software is the facilitation of a transition towards sustainable manufacturing practices.

By enabling the production of intricate, lightweight parts and components, the software has contributed to the reduction of material consumption and overall waste generation in the manufacturing process.

This shift towards sustainable manufacturing aligns with the growing emphasis on environmental responsibility and resource efficiency, positioning organizations as leaders in responsible production practices.

Future Prospects And Advancements In Magics 3d Printing Software

The future of Magics 3D Printing Software holds promising prospects with its continuous advancements and innovative technologies.

As the 3D printing industry continues to expand, Magics software is at the forefront of incorporating cutting-edge features and enhancements to meet the evolving needs of users and stay ahead of the competition.

1. Integration Of Artificial Intelligence

The integration of artificial intelligence (AI) in Magics 3D Printing Software marks a revolutionary step towards optimizing the 3D printing process.

With AI capabilities, the software is able to analyze and optimize designs, detect potential errors, and streamline the overall production workflow, thereby enhancing efficiency and precision.

2. Enhancements In Material Compatibility

Magics 3D Printing Software is making significant strides in material compatibility, continually expanding its capabilities to support a wider range of materials.

This allows users to leverage diverse materials, from traditional plastics to advanced composites, opening up new possibilities for innovative and functional 3D printed objects.

3. Market Expansion And Adoption Trends

The market expansion and adoption trends of Magics 3D Printing Software depict its increasing popularity and widespread acceptance among industries and businesses.

As more organizations recognize the value of 3D printing for rapid prototyping, custom manufacturing, and product development, the demand for Magics software is expected to soar, propelling its growth in the global market.

Frequently Asked Questions For Magics 3d Printing Software

What Are The Key Features Of Magics 3d Printing Software?

Magics 3D Printing Software offers advanced slicing, nesting, and support generation features, enabling seamless integration with various 3D printing processes. Its comprehensive toolset includes mesh editing, file preparation, and analysis capabilities, making it a versatile solution for additive manufacturing.

How Does Magics 3d Printing Software Streamline Workflow?

Magics 3D Printing Software facilitates efficient processing of 3D models by providing automated repair functionalities, precise measurement tools, and customizable build platforms. Its ability to optimize part orientation and generate intelligent support structures significantly streamlines the additive manufacturing workflow, reducing time and costs.

Can Magics 3d Printing Software Handle Complex Geometries?

Yes, Magics 3D Printing Software excels in handling intricate geometries, allowing for the efficient processing of complex 3D models. With its advanced mesh repair and modification tools, the software ensures high-quality print outcomes for intricate designs, making it ideal for industries requiring precision and intricacy in their 3D prints.

Conclusion on Magics 3d Printing Software

Magic’s 3D printing software offers an innovative solution for seamless design and production.

The user-friendly interface, diverse features, and precise results make it a stand-out option in the industry.

With its ability to streamline the entire printing process, Magic’s software is a game-changer for businesses and individuals alike, ensuring efficient and high-quality 3D printing experiences.