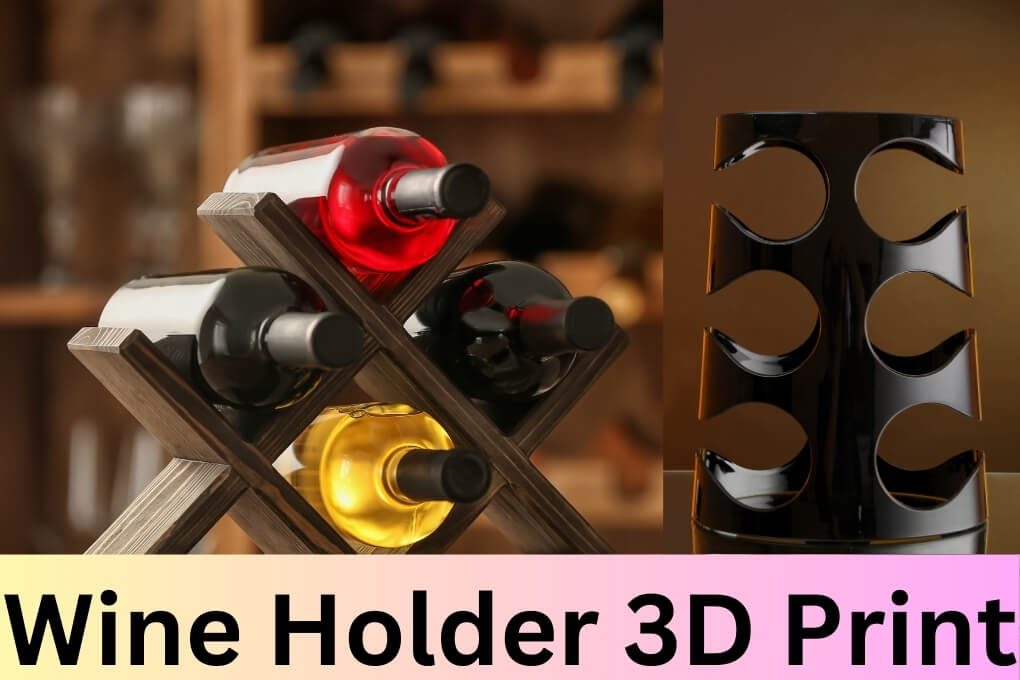

A wine holder 3D print is a practical and stylish way to display and store your favorite bottles of wine.

Whether you are a wine connoisseur or simply enjoy a glass every now and then, having a wine holder can add a touch of elegance to your home decor.

With the advancements in technology, 3D printing has become increasingly popular, allowing for the creation of unique and customized wine holders. In this article, we will explore the benefits of using a wine holder 3D print and how it can enhance your wine-drinking experience.

I. Benefits of 3D Printing Wine Holders

When it comes to storing and displaying wine, a 3D printed wine holder can offer numerous benefits. As someone who has explored the world of 3D printing, I have discovered the advantages of creating unique and customized wine holders using this technology.

1. Customization

One of the main advantages of 3D printing wine holders is the ability to customize the design to fit your specific needs and preferences. With traditional wine holders, you are limited to the designs available in stores. However, with 3D printing, you have the freedom to create a wine holder that perfectly matches your style and the aesthetics of your home.

2. Unique Designs

3D printing allows you to bring your creative ideas to life and create unique wine holders that cannot be found anywhere else. Whether you prefer a modern and minimalist design or a more intricate and artistic piece, 3D printing gives you the opportunity to design and produce a wine holder that stands out from the rest.

3. Cost-Effective

Contrary to popular belief, 3D printing can be a cost-effective option for creating wine holders. While the initial investment in a 3D printer may seem significant, the ability to print multiple wine holders at a lower cost compared to purchasing them individually can result in long-term savings. Additionally, 3D printing allows you to use materials that are more affordable, such as PLA filament, without compromising on quality.

4. Faster Production

With traditional manufacturing methods, producing wine holders can be a time-consuming process. However, 3D printing offers a faster production time, allowing you to create wine holders in a matter of hours or days, depending on the complexity of the design. This is particularly beneficial if you need to create multiple wine holders for an event or as gifts.

5. Sustainability

As the world becomes more conscious of the environmental impact of manufacturing processes, 3D printing stands out as a more sustainable option. By using biodegradable materials and reducing waste through precise printing, 3D printing wine holders can help minimize your carbon footprint and contribute to a greener future.

II. Factors to Consider When Designing a 3D Printed Wine Holder

When it comes to designing a 3D printed wine holder, there are several factors that need to be taken into consideration to ensure a successful and functional end result.

Here are some key factors to keep in mind:

- Size and Shape: The size and shape of the wine holder should be carefully considered to accommodate different bottle sizes and shapes. It should provide a secure and stable fit for the wine bottle.

- Material: The choice of material for the wine holder is crucial as it determines the durability and aesthetic appeal of the final product. Factors such as strength, flexibility, and heat resistance should be considered. Popular materials for 3D printed wine holders include PLA, ABS, and PETG.

- Design Complexity: The complexity of the design should be taken into account, as intricate designs may require more time and resources to print. Simple and sleek designs are often preferred for their ease of printing and clean aesthetic.

- Functionality: The wine holder should not only serve as a decorative piece but also provide functionality. Consider incorporating features such as a handle for easy transportation or a slot for holding wine glasses.

- Customizability: One of the major advantages of 3D printing is the ability to customize designs. Consider adding personal touches such as initials, patterns, or logos to make the wine holder unique and personalized.

- Printability: It is important to consider the printability of the design. Ensure that the chosen design can be printed without any major issues such as overhangs, thin walls, or excessive support material requirements.

- Post-Processing: After printing, the wine holder may require post-processing to achieve a polished and finished look. Consider techniques such as sanding, painting, or applying a clear coat to enhance the appearance of the final product.

By taking these factors into account, you can design a 3D printed wine holder that not only looks great but also functions effectively. Whether you are creating a wine holder for personal use or as a unique gift, the possibilities with 3D printing are endless.

III. Popular Designs for 3D Printed Wine Holders

When it comes to 3D printed wine holders, the possibilities are endless. With the flexibility and creativity that 3D printing offers, there are numerous popular designs that can add a touch of elegance and uniqueness to your wine collection.

Here are some of the most sought-after designs:

1. Geometric Wine Holder

Geometric wine holders are a popular choice for those who appreciate modern and minimalist designs. These holders often feature intricate geometric patterns that create a visually stunning display for your wine bottles. Whether it’s a simple hexagonal design or a more complex fractal pattern, a geometric wine holder is sure to impress your guests.

2. Spiral Wine Holder

The spiral wine holder is a classic design that never goes out of style. Its sleek and elegant shape allows for easy access to your wine bottles while adding a touch of sophistication to your home decor. Whether you opt for a single spiral or a double helix design, this type of wine holder is sure to make a statement.

3. Animal-inspired Wine Holder

For those who want to add a whimsical touch to their wine collection, animal-inspired wine holders are the way to go. From a graceful swan to a playful elephant, these holders come in various animal shapes and sizes. Not only do they serve as functional wine holders, but they also double as eye-catching conversation starters.

4. Modular Wine Holder

If you’re looking for a wine holder that can grow with your collection, a modular design is the perfect choice. These holders consist of individual pieces that can be assembled and rearranged to accommodate any number of wine bottles. With a modular wine holder, you have the flexibility to expand or contract your wine storage as needed.

5. Personalized Wine Holder

For a truly unique and personalized touch, consider a custom-designed wine holder. With 3D printing, you can bring your own design ideas to life. Whether it’s incorporating your initials, a family crest, or a favorite quote, a personalized wine holder adds a special touch to your wine collection.

When choosing a design for your 3D printed wine holder, consider your personal style, the size of your wine collection, and the overall aesthetic of your space. With the endless possibilities that 3D printing offers, you’re sure to find a design that perfectly complements your taste.

IV. Tips for Printing and Finishing a 3D Printed Wine Holder

When it comes to printing and finishing a 3D printed wine holder, there are several tips and tricks that can help you achieve the best results. Whether you are a beginner or an experienced 3D printer, these tips will ensure that your wine holder turns out beautifully.

1. Choose the Right Material

One of the most important factors to consider when printing a wine holder is the material you use. While there are various options available, it is recommended to choose a material that is strong, durable, and food-safe. PLA (polylactic acid) is a popular choice for 3D printing wine holders as it meets these requirements and offers a smooth finish.

2. Optimize the Design

Before printing your wine holder, it is crucial to optimize the design. This involves ensuring that the dimensions are suitable for holding wine bottles securely and that the structure is stable. Additionally, consider adding features such as a handle or decorative elements to enhance the aesthetics of the wine holder.

3. Use Supports if Necessary

Depending on the complexity of your wine holder design, it may require the use of supports during printing. Supports are temporary structures that help prevent overhangs and ensure the print is successful. However, it is important to carefully remove the supports after printing to avoid damaging the wine holder.

4. Pay Attention to Print Settings

When printing a wine holder, pay attention to the print settings to achieve the desired outcome. Adjust parameters such as layer height, infill density, and print speed based on the material and design of your wine holder. Experimenting with different settings can help you find the optimal balance between print quality and print time.

5. Post-Processing and Finishing

Once your wine holder is printed, it’s time to post-process and finish it. Start by removing any support structures or rafts carefully. Then, use sandpaper or a file to smooth any rough edges or imperfections. If desired, you can also apply primer and paint to add a personal touch to your wine holder.

6. Test the Wine Holder

Before using your 3D printed wine holder, it is essential to test it with an actual wine bottle. This will ensure that the dimensions and stability are suitable for holding the bottle securely. Make sure the wine holder provides a snug fit and that the bottle does not wobble or tip over.

By following these tips for printing and finishing a 3D printed wine holder, you can create a functional and visually appealing accessory for your wine collection. Remember to always prioritize safety and quality when designing and printing your wine holder.

Frequently Asked Questions about Wine Holder 3D Print

What is a 3D printed wine holder?

A 3D printed wine holder is a wine bottle storage solution that is created using a 3D printer. It is designed to securely hold wine bottles in a stylish and unique way.

How does a 3D printed wine holder work?

A 3D printed wine holder is designed with specific dimensions and features that allow it to hold a wine bottle securely. The design typically includes openings or slots to accommodate the neck and base of the bottle, ensuring it remains stable and upright.

Are 3D printed wine holders durable?

Yes, 3D printed wine holders can be quite durable depending on the material used for printing. Common materials like PLA or ABS are strong and sturdy, making them suitable for holding wine bottles safely.

Can I customize the design of a 3D printed wine holder?

Yes, one of the advantages of 3D printing is its ability to create customized designs. You can modify the dimensions, patterns, and even add personalized elements to create a unique wine holder that suits your taste.

What types of wine bottles can be held in a 3D printed wine holder?

Most 3D printed wine holders are designed to hold standard-sized wine bottles. However, it’s always a good idea to check the specifications of the specific wine holder you are interested in to ensure compatibility.

Can a 3D printed wine holder be used for other types of bottles?

While designed specifically for wine bottles, some 3D printed wine holders may also accommodate other similarly sized bottles like champagne, liquor, or olive oil bottles. Again, it’s important to check the specifications of the wine holder to confirm compatibility.

Are 3D printed wine holders easy to clean?

Yes, most 3D printed wine holders can be easily cleaned with mild soap and water. However, it’s essential to refer to the manufacturer’s instructions or recommendations for the specific material used in the wine holder.

Can I purchase a pre-designed 3D printed wine holder?

Yes, there are numerous pre-designed 3D printed wine holders available for purchase online. You can choose from a variety of styles and designs to find the one that best suits your preferences.

How much does a 3D printed wine holder cost?

The cost of a 3D printed wine holder can vary depending on factors such as design complexity, material used, and where you purchase it from. On average, you can expect to find 3D printed wine holders ranging from $10 to $50.

Can I 3D print my own wine holder at home?

Yes, if you have access to a 3D printer and the necessary design files, you can 3D print your own wine holder at home. There are numerous free or paid designs available online that you can use to create your custom wine holder.

Conclusion on 3D Printed Wine Holders

With the advent of 3D printing technology, creating a custom wine holder has never been easier. By harnessing the power of 3D design software and utilizing the capabilities of a 3D printer, wine enthusiasts can now have a personalized and unique wine holder that perfectly matches their style and preferences.

Whether it’s a sleek and modern design or a rustic and vintage-inspired piece, the possibilities are endless. So why settle for a generic wine holder when you can have one that truly reflects your taste? Embrace the future of wine storage with a 3D printed wine holder today.